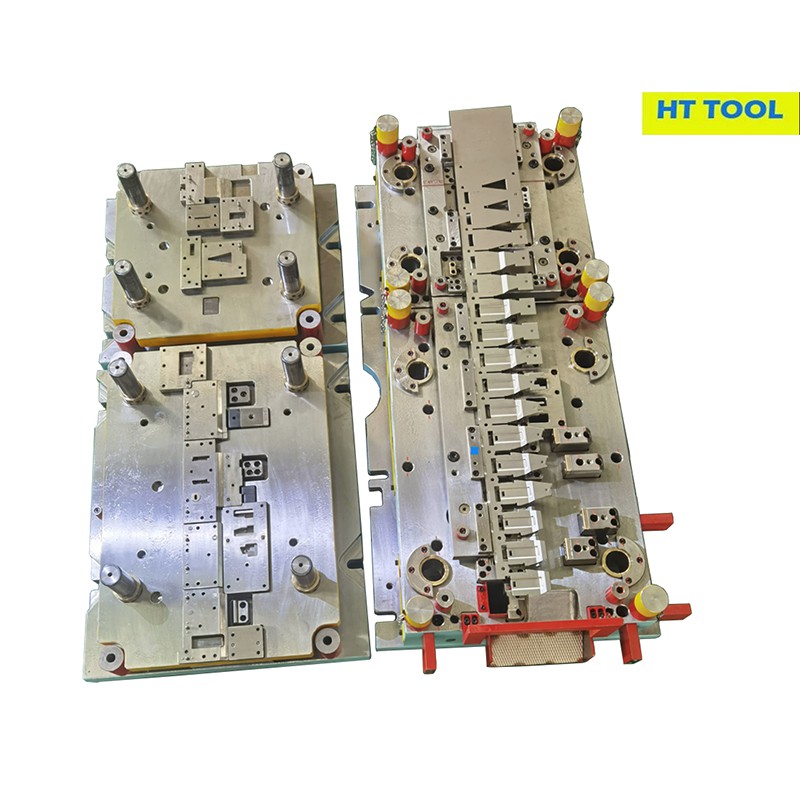

Metal Stamping Tool And Die

Product size:3100L*950W*650H

Material:Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc.

Product Introduction

At HT tool and Die, we specialize in high-quality metal stamping tool and die designed for precision, durability, and efficiency. Our advanced tooling solutions cater to industries such as automotive, aerospace, electronics, and appliance manufacturing, ensuring flawless production of complex metal components.

Product Specification

|

Product Name |

Metal Stamping Tool And Die |

|

Item No. |

HTSD-007 |

|

Product size |

3100L*950W*650H |

|

Material |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Material thickness |

0.5-8mm or customized |

|

Machining Process |

Milling,Grinding,Boring,CNC,EDM,WEDM,Precision Flat Milling |

|

Press try-out |

200-800T press machines |

|

Inspection |

CMM,3D laser scanner,Alloy Analyzer,Micro-Calliper,Vision Projector |

|

Forming Way |

Punching,Blanking,Piercing,Forming, Deep Drawn |

|

Precision Accuracy |

High precision machining,min.0.02 |

|

Standard Component |

MISUMI,PUNCH,FIBRO,DAYTON,DANLY etc. |

|

Surface treatment |

Zinc plated, powder coated, painting, polishing, brushing, chrome plating, anodizing, sandblasting, etc. |

|

Machining Equipment |

CNC,EDM,Argie Charmilles,Milling Machine,3DCMM, |

|

Logo Method |

Laser engraving, CNC engraving |

|

Industry application |

Automotive,Home appliance, Electronics, Aero-space |

|

Design files format |

STEP,DWG,CAD,STP,PRT,CATIA,PDF |

|

Testing Facility |

Three coordinate measuring machine,Micrometer,calipers,3D scanner |

|

Production capability |

150sets annually for progressive tool sheet metal |

1,Our capability

CAE Analysis:By simulating the stamping process, CAE analysis helps identify potential issues such as material thinning, wrinkling, cracking, or springback before the metal stamping tool and die goes into production. This predictive capability allows manufacturers to optimize tool design, select appropriate materials, and fine-tune process parameters, significantly reducing the risk of defects and costly rework.Accurate CAE analysis helps to improve parts quality and optimize progressive metal stamping transfer die and other stamping tooling process. Concurrent engineering, product design review, and early involvement can help shorten the project lead-time.This is example of our progressive metal stamping CAE simulation:

CAE simulation

3D transfer die simulation

Metal Stamping Tool and Die designing:In the tool design department, we are able to provide our customers with a full range of services. Engineers use AUTOFORM to ensure the manufacture ability of stampings and simulation (studies from cracks, wrinkles, rebound, compensation, videos, etc. are available). For complete 3D / 2D tooling design, our designers (x9) use UG software.

3D progressive metal stamping design

Metal Stamping Tool And Die Buy off process

Why choose us for your metal stamping production

Why Choose Our Metal Stamping Tool & Die Services?

✔ Custom Engineering – Tailored designs to meet exact specifications

✔ High Precision – Advanced CNC machining for tight tolerances

✔ Durability – Premium materials and heat treatment for extended tool life

✔ Fast Turnaround – Efficient production with minimal downtime

✔ Cost-Effective – Optimized solutions to reduce long-term manufacturing costs

Our certficate ISO9001:2015 and IATF 16949:2016

Our process flow for Metal Satmping Tool and Die production

Our equipment lists for Metal Stamping Tool and Die production

|

Item No. |

Equipment |

Specification (mm) |

QTY |

|

1 |

Press Machine |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Three-in-one feeding machine |

Width 600mm,thickness 0.5- 4.5mm |

1 |

|

5 |

Three-in-one feeding machine |

Width 1200mm,thickness 0.5- 6.0mm |

1 |

|

6 |

CNC |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Surface Grinding Machine |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Manual Grinding Machine |

150*400 |

2 |

|

10 |

Vertical Drilling Machine |

ф1~32 |

3 |

|

11 |

Radial Drilling Machine |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Milling Machine |

1150*500*500 |

2 |

|

14 |

Normal Wire Cutting Machines |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Fast Wire Cutting Machines |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Stoma EDM |

300*200 |

1 |

|

19 |

3D Scanner |

650*550 |

1 |

FAQ

Q: 1. What is a metal stamping tool and die?

A: A metal stamping tool and die is a precision tool used in stamping parts manufacturing to cut, shape, or form metal sheets into specific parts. The die acts as a mold, while the stamping press applies force to create the desired component.

Q: 2. What types of stamping dies do you offer?

A: HT Tool&Die provides a variety of metal stamping tool and die, including:

Progressive dies (for high-speed, multi-stage forming)

Transfer dies (for complex, large parts)

Compound dies (for combined cutting and forming in one stroke)

Blanking dies (for precise flat-part cutting)

Q: 3. What materials can be processed with your stamping dies?

A: Our dies are designed to work with various metals, including:

Steel (cold-rolled, stainless, etc.)

Aluminum

Copper & brass

High-strength alloys

Q: 4. How do you ensure the durability of your metal stamping tool and die?

A: We use high-quality tool steel (D2, A2, carbide) and apply heat treatment, precision grinding, and coatings (such as TiN or CrN) to enhance wear resistance and extend tool life.

Q: 5. What industries do you serve with your stamping tool and die?

A: Our solutions support industries such as:

✅ Automotive (structure parts,chassis,seating system,brackets, connectors)

✅ Electronics (shielding, contacts)

✅ Aerospace (structural components)

✅ Appliances (housings, panels)

Q: 6. Can you customize dies for specific part requirements?

A: Yes! At HT tool and Die we offer fully customized die designs based on your part drawings, material specs, and production volume needs.

Q: 7. What is the typical lead time for a custom stamping die?

A: Lead times vary based on complexity, but we optimize production for fast turnaround (typically 12-22 weeks for standard dies).

Q: 8. How do you maintain quality control in die manufacturing?

A: We use CNC machining, CMM inspection, and rigorous testing to ensure every die meets precise tolerances and performance standards.

Q: 9. Do you provide tool maintenance and repair services?

A: Yes, At HT tool and Die we offer die maintenance, sharpening, and repair to maximize longevity and performance.

Hot Tags: metal stamping tool and die, China metal stamping tool and die manufacturers, suppliers, factory, Electronic Connection Device, Other Metal Stamping Dies, Auto Electrical Equipment Parts, Aluminum Machining Component, Auto Upper Body Parts, Electronic Components

You Might Also Like

Send Inquiry