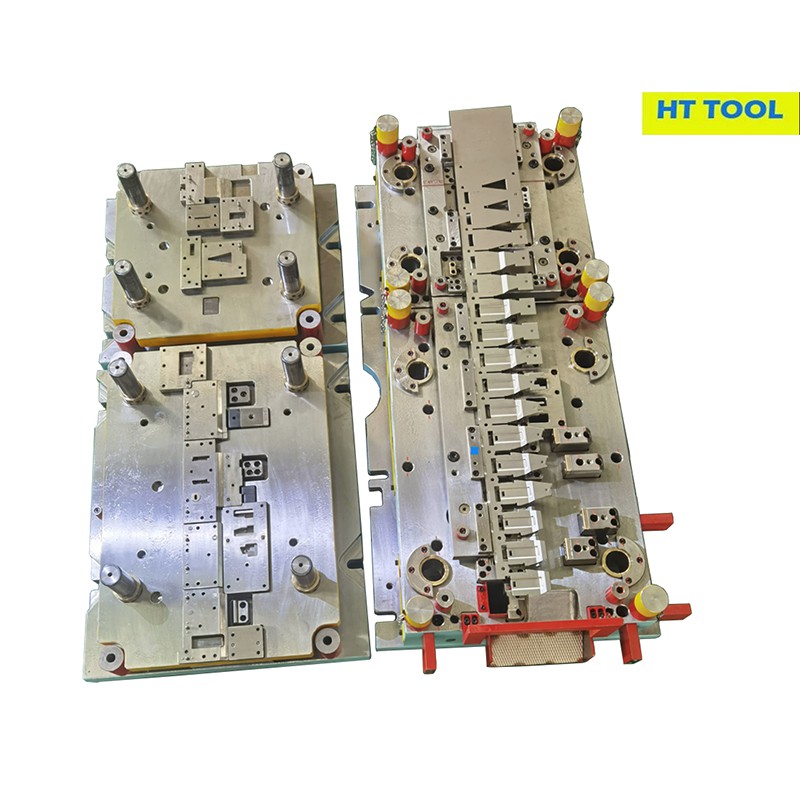

Compound Tool And Progressive Tool

Product size:2500L*700W*550H

Material:Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc.

Products Description

|

Product Name |

Compound Tool and Progressive tool |

|

Item No. |

HTSD-004 |

|

Product size |

2500L*700W*550H |

|

Material |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Material thickness |

0.5-8mm or customized |

|

Surface treatment |

Zinc plated, powder coated, painting, polishing, brushing, chrome plating, anodizing, sandblasting, etc. |

|

Machining Equipment |

CNC,EDM,Argie Charmilles,Milling Machine,3DCMM, |

|

Logo Method |

Laser engraving, CNC engraving |

|

Industry application |

Automotive,Home appliance, Electronics, Aero-space |

|

Packaging |

Wooden box or at your request |

|

Testing Facility |

Three coordinate measuring machine,Micrometer,calipers,3D scanner |

|

Production capability |

150sets annually |

Introduction of compound tool and progressive tool:

Compound stamping dies are made with the help of compound die design. This die is made to carry out several tasks with each press stroke and they are used for cutting operations like blanking and piercing. Due to their ability to do tasks more quickly than simple stamping dies, compound stamping dies are more appropriate for intricate or difficult jobs.

Progressive tool stamping is ideal for long production runs due to its high repeatability. A single machine with multiple die stations is used in this metal stamping method. Each station where a stamping operation is performed automatically moves a metal strip of stock material. The finished part must then be cut free from the strip as the final step.

Compound tool and Progressive Tool Process

Compound tool and progressive tool offers a cost-effective and efficient method for producing large-volume runs by utilizing a progressive die. The die contains several stamping stations that perform unique forming operations as a strip of sheet metal is fed through the machine. Combining the necessary stamping tools into one die set improves the efficiency of the stamping project.

The following components are essential to a progressive die:

❆Die Set

❆Die Buttons (bushings)

❆Punches

❆Punch Holder

❆Plate (section)

❆Pins

❆Slug Clearance

❆Stripper

Compound tool and progressive too may also include features such as sub-liners, stop blocks, slides, or sensors. The primary goal of these components is to ensure accurate handling of the material.

Progressive metal stamping follows these steps:

The progressive die is positioned inside a reciprocating stamping press.

The press moves up, bringing the top die with it and allowing the metal strip to feed into the equipment.

When the press moves downward, the die closes to execute the stamping operation.

A finished part is released from the die with each stroke of the press.

The final cutoff station separates the finished parts from the conveying web.

Our Services

CAE Analysis:Accurate CAE analysis helps to improve parts quality and optimize progressive metal stamping transfer die and other stamping tooling process. Concurrent engineering, product design review, and early involvement can help shorten the project lead-time.This is example of our progressive metal stamping CAE simulation:

CAE simulation

3D transfer die simulation

Stamping die designing:In the tool design department, we are able to provide our customers with a full range of services. Engineers use AUTOFORM to ensure the manufacturability of stampings and simulation (studies from cracks, wrinkles, rebound, compensation, videos, etc. are available). For complete 3D / 2D tooling design, our designers (x9) use UG software.

3D progressive metal stamping design

3D transfer die design

Project management:For each progressive metal stamping project, we will assign one project engineer to manage the whole procedure from concept of the very beginning to perfect completion. We have a wonderful project management team, who owns strong engineering background and good at English communication. This helps your project goes smoothly and well under control. We will keep customer updated about detail information of this project by weekly report and updated pictures. It is easy for customer to manage the project at the same time. We will provide high standard of customer service by self-improvement. Just one phone call, or an e-mail, and you'll see we are ready for you anytime.

Production cost optimization:When closely working with customers from process planning till tool designing, we always spend a lot of resources and efforts on maximizing the rates of material utilization & press stroke and minimizing the tool station numbers while ensuring production stability and repeatability.

Stamping die manufacture:HT TOOL is able to creat progressive metal stamping in-house to meet all of our customer needs. Our engineering department works with our talented staff to ensure the quality of your parts.The below chart is our machining equipment list:

|

Item No. |

Equipment |

Specification (mm) |

QTY |

|

1 |

Press Machine |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Three-in-one feeding machine |

Width 600mm,thickness 0.5- 4.5mm |

1 |

|

5 |

Three-in-one feeding machine |

Width 1200mm,thickness 0.5- 6.0mm |

1 |

|

6 |

CNC |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Surface Grinding Machine |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Manual Grinding Machine |

150*400 |

2 |

|

10 |

Vertical Drilling Machine |

ф1~32 |

3 |

|

11 |

Radial Drilling Machine |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Milling Machine |

1150*500*500 |

2 |

|

14 |

Normal Wire Cutting Machines |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Fast Wire Cutting Machines |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Stoma EDM |

300*200 |

1 |

|

19 |

3D Scanner |

650*550 |

1 |

Stamping die tryout:We have Mechanical Press from 200T up to 800T

200T Mechanical Press

Max table size: 2400*840*550mm

400T Mechanical Press

Max table size: 3300*1500*750mm

800T Mechanical Press

Max table size: 4200*1800*1200mm

One-stop shop service:As a professional progressive metal stamping manufacturer in the Chinese tooling industry with solid capability and substantial capacity, HT Tool and Die offers an integral solution to customers by designing & building cold & hot-forming tools, checking fixtures and welding jigs in the global automotive industry.

The Comparison Between Stamping Dies: Simple vs. Compound die vs. Progressive metal stamping vs. Transfer Dies

|

Feature |

Simple Die |

Compound Die or Combination Die |

Progressive metal stamping |

Transfer Die |

|

Operations |

Single operation |

Multiple operations (single stroke). Very limited to design. |

Multiple operations (sequence). Slightly limited to design. Some complex drawing operations would require a transfer die |

Multiple operations (transfer between stations). Any operation process is possible. |

|

Stations |

One station |

One station |

Multiple stations |

Multiple stations |

|

Complexity |

Low |

Low to medium |

High complexity |

High complexity |

|

Mold testing and set up |

Easy |

Difficult |

Moderate. Modules reduce complexity and increase set up efficiency. |

Usually easier than progressive, but requires transfer and lifting devices that are also complex to design. |

|

Efficiency |

Very low |

Low |

Very high |

High. Slower than progressive given the required transfer operations. |

|

Cost |

Low tooling cost, high part unit cost |

Medium tooling cost, medium part unit cost |

High tooling cost, very low part unit cost |

Normally higher tooling and unit cost than progressive |

|

Production volume |

Low volume |

Medium to high volume |

High volume (appropriate for mass production) |

High volume, (appropriate for mass production) |

|

Suitability |

Simple parts |

Simple parts |

Complex parts |

Larger and/or concave parts, complex parts |

|

Material utilization rate |

Moderate to high |

Moderate to high |

Moderate. The need for pilots and carriers can reduce material utilization. A good design can highly reduce the scrap produced. |

Moderate to high |

|

Blanking operation |

1 stroke |

1 stroke |

The last operation |

The first operation |

Compound tool and progressive tool Application:

Shipping&Package for Compound tool and progressive tool:

Lead time for Compound tool and progressive tool:

|

|

Progressive Tool |

Compound Tool |

||||

|

Lead time |

Small dies ( ≦ 1 M ) Weeks |

Medium Size ( 2 M-3M ) Weeks |

Large Size (3M- ) Weeks |

Small Size ≦2000 mm weeks |

Medium dies 2000-3000mm weeks |

Large Size ≥3000mm weeks |

|

Simulation |

2 -3.5 wks |

3.5 -5.5 wks |

5.5 wks |

2 -3.5 wks |

3.5 -5.5 wks |

6 wks |

|

Design |

||||||

|

Pattern |

|

|

|

0.5 wks |

0.5 wks |

1 wks |

|

Casting/steel |

0.5 -1 wks |

1 wks |

1.5 wks |

3 weeks |

4 weeks |

4 wks |

|

Manufacturing |

2.5 -3.5 wks |

3.5 -5.5 wks |

7 wks |

2.5 -4 wks |

3.5 - 5.5 wks |

7 wks |

|

Heat treatment |

||||||

|

Assembly |

3 - 4 wks |

5 - 10 wks |

10 wks |

3 - 4 wks |

5 - 10 wks |

10 wks |

|

Laser cut parts |

||||||

|

Off tool parts |

||||||

|

OK Parts |

||||||

|

Buy off |

||||||

|

Total |

8 -12 wks |

13 -22 wks |

24 wks |

11 -15 wks |

16.5 -25.5 wks |

28 wks |

FAQ:

What are the different types of dies?

✹Different Types of Dies

✹Simple Die.

✹Compound Die.

✹Progressive Die.

✹Transfer Die.

✹Combination Die.

✹Multiple Die.

✹Round split Die.

✹Adjustable Die.

Definition and Process for Compound Tool?

Compound Tool Stamping differs from Progressive Tool Stamping in completing multiple operations – such as cutting and forming – in a single stroke. This method is akin to a chef performing several cutting tasks in one swift motion.

It's particularly effective for producing flat parts, where multiple features must be added simultaneously. This single-stroke approach ensures high precision and alignment, making it ideal for parts with paramount dimensional accuracy.

Advantages of Compound Tool Stamping?

The primary advantage of Compound Tool Stamping is its precision. Since multiple operations are executed in a single stroke, the risk of misalignment between processes is minimized, resulting in highly accurate parts.

This method is also efficient for producing flat components, as it reduces the number of hits needed compared to other methods, thereby speeding up production.

Additionally, Compound Tool Stamping tends to generate less scrap material, contributing to cost savings and environmental sustainability.

Disadvantages and Limitations of Compound tool

The limitations of Compound Tool Stamping include its lower production speed than Progressive Tool Stamping, as it's generally used for more detailed and precise work rather than high-speed mass production.

Moreover, there are better methods for complex parts that require multiple bending or forming operations. The complexity and depth of parts that can be produced are limited, which means this method is best suited for simpler, flatter components.

Hot Tags: compound tool and progressive tool, China compound tool and progressive tool manufacturers, suppliers, factory, Auto Bracket Parts, Auto Electrical Equipment Parts, Stamping Parts, metal mould air fryer, Tandem Die, Washing Machine Die

Previous

Progressive Tool Sheet MetalNext

Prototype DieYou Might Also Like

Send Inquiry