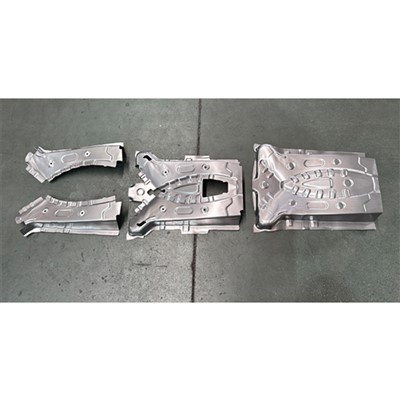

Steel sheet progressive die

Thickness:2.0mm

Die Size: 2980x1025x700mm

Part Size: 23x125x30mm

Press Tonnage:630T

Steel sheet progressive die can provide a variety of customization options, such as the optional part material thickness within the range of 0.2mm-8.0mm, and the optional pressure range of 200T to 800T. It has been developed through years of research and testing by our expert engineers to ensure it meets the highest standards of quality and performance. This die is made of high-strength, high-rigidity steel plate material, so it is wear-resistant, compressive and corrosion-resistant, which means it is not easily damaged and has a long service life. Additionally, we use state-of-the-art machinery and equipment to produce dies to the nearest thousandth of an inch, ensuring that each die is of the highest quality. With our dies, you can increase your output and shorten your production time, thus increasing your profit! Order now!

Basic Info.

|

Model NO. |

OEM |

|

Project |

Land Rover |

|

Transport Package |

Standard |

|

Specification |

Customized |

|

Origin |

Dongguan, China |

|

Dongguan, China |

100000PCS/Year |

Product Description

|

Sheet Metal Stamping Fabrication |

|

|

Product Name: |

OEM Metal Steel Sheet Progressive Die Stamping Parts |

|

Material Capacity: |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Material Thickness: |

0.5-8mm or customized |

|

Surface Finishing: |

Zinc plated, powder coated, painting, polishing, brushing, chrome plating, anodizing, sandblasting, etc. |

|

Process Capability: |

Stamping, bending, deep drawing, welding, laser cutting, CNC turning, milling,drilling, etc. |

|

Professional level: |

Adhering rigorously to technical specifications to uphold product strength and precision, engaging in expert negotiation on techniques, ensuring prompt production, maintaining quality assurance, conducting thorough 100% inspections, and facilitating swift and convenient shipping logistics. |

|

Samples service: |

Available |

|

Trade Term: |

EXW DONGGUAN.CHINA |

|

Payment Term: |

T/T |

|

Delivery: |

Tool:8-9weeks |

Why chose us?

1.Our Service

The service scope of steel sheet progressive die includes, but is not limited to:

1. Design and fabrication of steel sheet progressive dies: Crafting a variety of steel sheet progressive dies, such as punches, die holders, and templates, tailored to the specifications provided by clients.

2. Customization services: Tailoring steel sheet progressive dies according to clients' provided drawings or samples, ensuring alignment with their specific requirements.

3. Maintenance and repair of dies: Offering upkeep and repair services for existing steel sheet progressive dies to uphold their performance and longevity.

4. Technical assistance: Providing specialized technical support, encompassing consultations on optimizing die design and refining production processes.

5. Quality assurance: Implementing stringent oversight throughout the steel sheet progressive die fabrication process to guarantee that the resulting products meet both industry standards and the expectations of our clients.

These offerings are crafted to address a diverse array of client needs within the realm of steel sheet progressive die processing, prioritizing both product excellence and manufacturing efficiency.

2.Equipment

Presses are equipped with automatic feeding and automatic chip removal functions, achieving automation and continuity in the manufacturing process. They complete the stamping process of metal sheets or other materials.

3.Partners

The steel sheet progressive die produced by HT TOOL are widely utilized in the automotive sector, exported to numerous countries across continents. Our dies have played a crucial role in the assembly of many renowned automotive components, meeting clients' manufacturing needs and making significant contributions to their production processes. This extensive exportation highlights HT TOOL's reputation for precision engineering and reliability in delivering high-quality dies that adhere to the rigorous standards of the automotive industry.

Final buy off with overseas customers

2.1 Definition Of Steel Sheet Progressive Die

Steel sheet progressive die is a type of die used for metal stamping processing, typically employed for continuous processing of metal sheets or strip materials. This type of die features multiple workstations, each performing specific operations such as cutting, forming, punching, etc. Metal sheets or strip materials pass through each workstation in the die sequentially, with each workstation completing one stamping operation before the workpiece moves to the next workstation for further processing. Through this continuous processing method, complex-shaped and precisely sized metal parts can be efficiently produced.

2.2 Benefits of Steel sheet progressive die

Progressive die stamping is a highly efficient and versatile manufacturing process used in the production of various metal components. When it comes to steel sheet progressive dies, there are several benefits:

High Efficiency: Progressive dies allow for multiple operations to be performed in a single press stroke, which significantly increases production rates compared to traditional stamping methods.

Cost-effectiveness:Despite the initial setup costs, progressive die stamping can be more cost-effective for high-volume production runs due to its speed and efficiency.

Precision and Accuracy: Progressive dies are engineered to perform precise and consistent stamping operations, ensuring uniformity and accuracy in the produced parts.

Complexity: Progressive dies can accommodate complex part geometries and features, including intricate bends, forms, and perforations, making them ideal for manufacturing components with demanding design requirements.

Reduced Material Waste: The streamlined nature of progressive die stamping minimizes material waste compared to other manufacturing processes, leading to cost savings and environmental benefits.

Increased Productivity: With multiple operations being performed simultaneously, progressive die stamping maximizes press uptime and overall productivity, resulting in higher output rates.

Scalability: Progressive die stamping is easily scalable to accommodate varying production volumes, making it suitable for both small-scale and large-scale manufacturing operations.

Cases

2.3 What are the main types of steel sheet Progressive die?

Steel sheet progressive dies can be categorized based on their design and the type of operations they perform. Here are some main types:

1

Multi-Station Progressive Die: Multi-station progressive dies have multiple stations, each dedicated to performing a specific operation. As the sheet metal advances through the die, it undergoes multiple operations simultaneously at different stations. This design increases efficiency and reduces production time.

2

Transfer Progressive Die: Transfer progressive dies combine the features of progressive dies with transfer systems. Instead of the metal strip advancing continuously through the die, individual blanks are transferred from one station to the next. This type of die is suitable for complex parts or when high accuracy is required.

3

Compound Die: While not strictly progressive dies, compound dies can be considered a type of progressive die in certain contexts. Compound dies perform multiple operations in a single press stroke but do not have the continuous strip feeding characteristic of typical progressive dies. They are often used for simpler parts with fewer operations

4

Tandem Line Progressive Die: In tandem line progressive dies, multiple presses are arranged in a line to perform sequential operations on the sheet metal. Each press in the line performs specific operations, and the part moves from one press to the next until all operations are completed. This setup is used for large and complex parts that cannot be produced in a single press.

These are some of the main types of steel sheet progressive dies, each designed to meet specific manufacturing requirements and produce a wide range of components efficiently and accurately

3.1 How to cooperate with us?

Since its establishment, HT TOOL has been providing metal progressive dies and services, including tool design, manufacturing, processing, and buy off. With customization capability, innovation, and tailored solutions for customers. It has ISO certification, quality inspection equipment, and strict quality management processes. It can provide customers with high-quality mold products that meet standards.

3.2 Certifications

3.3 Our Factory

HT TOOL & die is situated in Dongguan, known as the industrial hub of China, and was established in 2016. Specializing in hardware stamping dies and designs for automotive and electronics industries. Spanning across a 3,000 square meter standardized facility, we offer customers comprehensive hardware stamping die solutions and top-notch after-sales service.

HT TOOL & die boasts a complete array of processing and production equipment, enabling substantial production and processing capacity. Our primary focus lies in the production of hardware continuous molds, hardware transfer molds, and single process molds. We aim to deliver hardware stamping molds that are both reliable in performance and cost-effective, thereby facilitating less labor-intensive, cost-saving, and efficient production for our customers.

FAQ

Q: How is HT TOOL's steel sheet progressive die unique compared to other products in the market?

Q: What specific automotive manufacturing needs can HT TOOL's steel sheet progressive die address?

Q: In the design and manufacturing process, how does our team ensure the quality and performance of steel sheet progressive die?

Q: Does HT TOOL provide customized steel sheet progressive die solutions?

Q: Can HT TOOL's steel sheet progressive die adapt to parts of different specifications and sizes?

Q: What does the after-sales service include?

2. Technical support: Our technical team is available to provide support to customers, answering questions regarding the use, maintenance, and troubleshooting of the steel sheet progressive die.

Through our comprehensive after-sales service system, we are committed to providing customers with full support and assurance, ensuring that they can fully utilize the steel sheet progressive die to achieve their production goals and ensure the long-term stable operation of the equipment.

Q: Can using steel sheet progressive die improve production efficiency?

Q: Does steel sheet progressive die comply with international standards?

Q: What is the design cycle for steel sheet progressive die?

Q: How are orders processed?

Q: Does HT TOOL provide training services to help customers understand how to use steel sheet progressive die correctly?

Q: What types of automotive manufacturing processes can HT TOOL's products be used for?

Q: How is the material selection for steel sheet progressive die done?

Q: If provide steel sheet progressive die samples for testing?

Q: Does HT TOOL's products have corrosion resistance and wear resistance?

Q: What automotive parts production is HT TOOL's steel sheet progressive die suitable for?

Q: What is HT TOOL's pricing strategy?

Q: Can HT TOOL provide steel sheet progressive die customer cases or references?

Q: How are customer's steel sheet progressive die customization requirements handled?

Q: Can HT TOOL's after-sales support respond to customer inquiries and needs in real-time?

Hot Tags: Steel sheet progressive die, China Steel sheet progressive die manufacturers, suppliers, factory, Progressive Casting Die, Transfer Die, progressive die stamping, stamping automotive parts, Steel Sheet Progressive Die, Automotive Tooling

Previous

No InformationYou Might Also Like

Send Inquiry