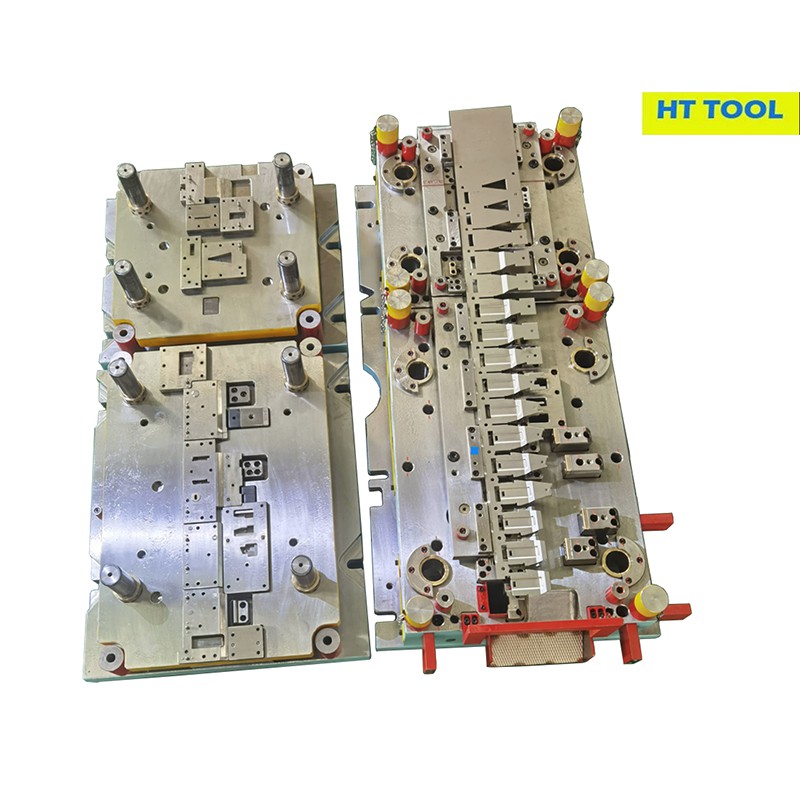

Progressive Tool Sheet Metal

Product size:2000L*580W*450H

Material:Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc.

Product Specification

|

Product Name |

Progressive Tool Sheet Metal |

|

Item No. |

HTSD-006 |

|

Product size |

2000L*580W*450H |

|

Material |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Material thickness |

0.5-8mm or customized |

|

Machining Process |

Milling,Grinding,Boring,CNC,EDM,WEDM,Precision Flat Milling |

|

Press try-out |

200-800T press machines |

|

Inspection |

CMM,3D laser scanner,Alloy Analyzer,Micro-Calliper,Vision Projector |

|

Forming Way |

Punching,Blanking,Piercing,Forming, Deep Drawn |

|

Precision Accuracy |

High precision machining,min.0.02 |

|

Standard Component |

MISUMI,PUNCH,FIBRO,DAYTON,DANLY etc. |

|

Surface treatment |

Zinc plated, powder coated, painting, polishing, brushing, chrome plating, anodizing, sandblasting, etc. |

|

Machining Equipment |

CNC,EDM,Argie Charmilles,Milling Machine,3DCMM, |

|

Logo Method |

Laser engraving, CNC engraving |

|

Industry application |

Automotive,Home appliance, Electronics, Aero-space |

|

Design files format |

STEP,DWG,CAD,STP,PRT,CATIA,PDF |

|

Testing Facility |

Three coordinate measuring machine,Micrometer,calipers,3D scanner |

|

Production capability |

150sets annually for progressive tool sheet metal |

Company brief introduction

Why choose us for your progressive tool sheet metal

Our certficate

Our process flow for progressive tool sheet metal production

Our equipment lists

|

Item No. |

Equipment |

Specification (mm) |

QTY |

|

1 |

Press Machine |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Three-in-one feeding machine |

Width 600mm,thickness 0.5- 4.5mm |

1 |

|

5 |

Three-in-one feeding machine |

Width 1200mm,thickness 0.5- 6.0mm |

1 |

|

6 |

CNC |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Surface Grinding Machine |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Manual Grinding Machine |

150*400 |

2 |

|

10 |

Vertical Drilling Machine |

ф1~32 |

3 |

|

11 |

Radial Drilling Machine |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Milling Machine |

1150*500*500 |

2 |

|

14 |

Normal Wire Cutting Machines |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Fast Wire Cutting Machines |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Stoma EDM |

300*200 |

1 |

|

19 |

3D Scanner |

650*550 |

1 |

Our quality control for progressive tool sheet metal

Quality is the soul of the brand, precision is the basis of the business. In order to ensure precise quality of progressive tool sheet metal, HT TOOL especially sets up a quality department, which is equipped with 3D measuring instrument, 3D handy scanner projector, height measuring instrument, sclerometer and other precision measuring tools. It strictly implements the ISO 9001 quality system requirements to precisely control all tools and stamping parts. QC inspector precisely test and adequately document the appearance, dimension and hardness of all components to ensure product quality. And then they will record the result to quality control system.

We are committed to our implementation of the zero-defect quality management philosophy. This quality sense has been implemented on each process. We also have very strict supplier verification system, and we execute the regular audit to assure the best quality raw materials. Only qualified suppliers can be our cooperators.

With advanced imported measuring devices and efficient control system, the quality of each progressive tool sheet metal is assured by our professional quality engineers from design to construction to sample to pre-shipment.

1. Strip Layout & Tool Design Control

2. Tool Steel Hardness Inspection

3. Cutting & Forming Steel Dimension Inspection

4. Tool Pre-Assembly Inspection

5. Samples CMM Inspection Report

6. Tool Buyoff Validation Report

7. Pre-Shipment Final Inspection

8. Export Tool Package Inspection

Our business partner

FAQ

Hot Tags: progressive tool sheet metal, China progressive tool sheet metal manufacturers, suppliers, factory, Turned Parts, Machined Parts, Prototype Die, Transfer Die, Medical and Fiber Optic Parts, Progressive Die Tooling

You Might Also Like

Send Inquiry