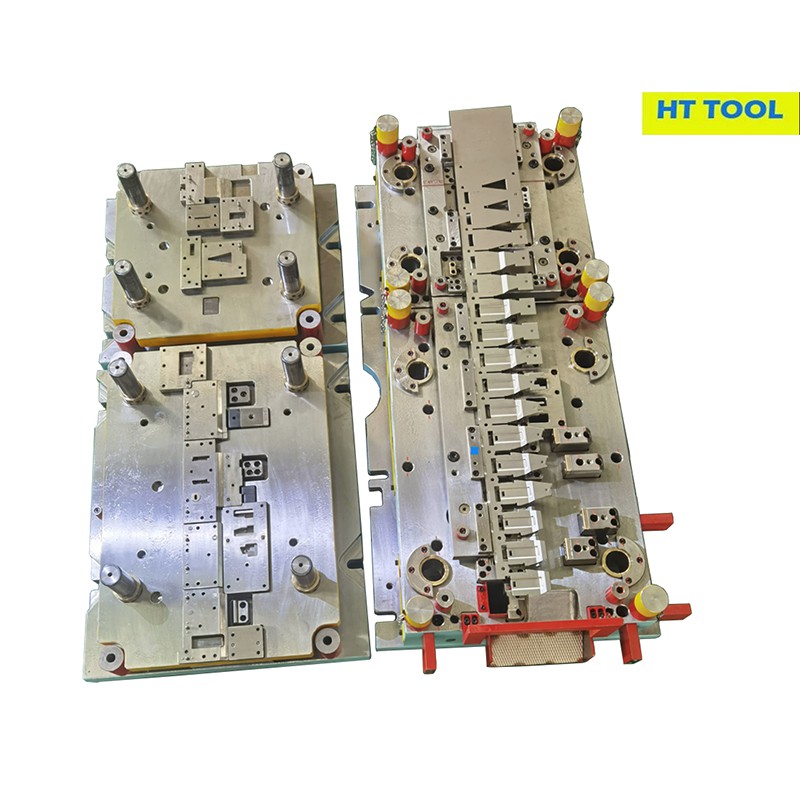

Progressive Sheet Metal Dies

Die Materials:S50c, SKD11, HMD5 etc..

Process Method:Forming,Piercing,Flange,Bending,Restrike,Trim,Idle,Pilot Piercing

Manufacturing Technology:Milling,Grinding,Boring,CNC,EDM,WEDM,Precision Flat Milling

Basic Info.

|

Model NO. |

HTSD-008 |

Die Materials |

S50c, SKD11, HMD5 etc.. |

|

Type of Die |

Progressive sheet metal dies |

Process Method |

Forming,Piercing,Flange,Bending,Restrike,Trim,Idle,Pilot Piercing |

|

Manufacturing Technology |

Milling,Grinding,Boring,CNC,EDM,WEDM,Precision Flat Milling |

Mold Cavity Technology |

CNC Milling |

|

Milling Speed |

High Speed |

Parts Detection Method |

CMM Coordinate Measuring Machine |

|

Surface Treatment |

Zinc plated, powder coated, painting, polishing,PVD,TD brushing, chrome plating, anodizing, sandblasting, etc. |

OEM |

OEM service provided |

|

Colour |

Customized |

|

Sea,Air,Rail Way |

|

Material Thickness |

0.6mm-8mm |

Transport Package |

Wooden case,steel frame |

|

Specification |

3700L*100W*850H |

HS Code |

8207300090 |

Product Description.

|

Product Name |

Progressive Sheet Metal Dies |

|

Machining Tolerance |

+/10.02mm~0.1 |

|

Material |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Process |

Machining & assembly |

|

Standard Components |

MISUMI,PUNCH,FIBRO,DAYTON,DANLY etc. |

|

Mould Life |

1.5million strokes or as per customer request |

|

Mould Type |

Progressive die,transfer die,tandem die |

|

Design Software |

2/3D, Auto CAD, Ug ,CATIA |

There is a diverse range of die types used for metal stamping, each of which perform different operations, such as cutting, trimming, notching, blanking, piercing, lancing, and shearing. Types of stamping dies include:

1.Blanking dies

2.Compound dies

3.Forming dies

4.Coining dies

5.Progressive dies

6.Transfer dies

HT TOOL&DIE offers many unique features to remain competitive within the industry, such as:

1.Full die design and development for unrivaled personalized production

2.Sharpening and maintaining tools to ensure consistency and design accuracy

3.EDM and CNC machining for the tightest tolerances on the market

4.Reverse engineering and diagnostics to ensure quick fixes when production errors arise, no unexpected delays, and smoother production

5.Aoto CAD and UG software etc.

6.Competitive pricing Rapid production and delivery

7.Professional, streamlined experience from start to finish for every customer

and also for secondary operations, laser cutting, bending, forming,and more

Progressive Sheet Metal Dies Product Pictures.

Who we are and what we can provide to you for Progressive Sheet Metal Dies

HT Tool&Die Co., Ltd was founded January 20,2016, mainly manufacture Progressive die, Transfer die, Tandem die and stamping parts.It is a professional tooling manufacturer integrating tooling design and manufacturing.The press machines from 80T to 800T

In the mold design phase

we collect the customer's needs and produce solutions designed to optimize the costs and times of production and maintenance of the die.

CNC Wire and EDM Machining

High precision machining ensuring finished parts with minimal roughness from superfinishing. We specialize in the processing of hard metal, a material that makes up the active parts of most of our progressive dies.

Die assembly and maintenance

Specific equipment and all the skills needed to intervene on any maintenance problem of the dies. Continuous, rapid and proactive assistance.

SUPERIOR MACHINERY FOR SHAPING PERFECT DIES

The machinery we use plays a key role in the success of production operations.

Thanks to automation and precision, we are also able to increase the speed of our service, always to the advantage of the customer.

01 QUOTATION&ORDER

Please feel free to contact us! HT Tool And Die Co.,Ltd

Please feel free to inquire about quotations and specifications.

We will cooperate with the relevant departments to make proposals that meet the needs of customers.

02 Progressive Sheet Metal Dies DESIGN

Experienced engineers will offer you the best proposal to meet your needs!

SE (Simultaneous Engineering)

We will help you from the early stages of your development. We find out problems and propose solutions both for feasibility verification using the latest software and process viability by experienced engineers. In addition, based on the production volume of the customer, it is possible to provide support such as proposing die specifications and selecting production facilities.

Progressive Sheet Metal Dies Strip Layout

The number of processes and the details of the process are determined based on the product data and equipment requirements received from customers. Even if the same product is designed differently, the number of processes and machining content will change. Therefore, we propose the most appropriate process settings based on the experience values.

3D design for Progressive Sheet Metal Dies

Design dies for each process by reflecting the customer's die specifications and equipment requirements based on the process contents defined in the D/L.

We independently verify the selection of mold parts and the validity of the designed mold drawings, and use software to verify the strength and mass productivity of each area.

CAE (mold/tooling simulation)

The forming analysis is performed by Autoform on the analysis model created based on the process defined by D/L. A threshold value is defined based on our experience, and a forming method is determined based on the analysis results.

03 Progressive Sheet Metal Dies Production

Shorten Lead Time And Improve Quality With 24-Hour Machining And Craftsmanship

Machining

Coordinated with NC Data Dept. to achieve automation by optimizing data settings based on various machining experience values and minimizing the intervention of machine operators to the limit. We are working to reduce lead time in die making by operating state-of-the-art machines around the clock.

Assembly

Progressive Sheet Metal Dies Assembly Process

Progressive dies are complex tools used in high-volume sheet metal stamping. Proper assembly ensures precision, durability, and efficient production. Below is a step-by-step guide to assembling progressive dies.

1. Preparation Before Assembly

A. Verify Components & Documentation

Check all die components (punches, dies, strippers, guide pins, springs, etc.) against the BOM (Bill of Materials).

Review engineering drawings and assembly instructions.

Ensure material certificates (for tool steel, carbide inserts) are available.

B. Clean & Inspect Components

Remove burrs, sharp edges, and debris from machined parts.

Check for wear, cracks, or machining errors in critical components.

Apply rust preventive oil if storage is required before assembly.

04 QUALITY ASSURANCE

Thorough Inspections And Quality Assurance By A Skilled Inspector

Panel Quality Assurance

In addition to the contact type 3D measuring equipment, non-contact blue light 3D measuring equipment was installed at each factory, enabling more precise product quality checks. This is used to improve the quality of our products, mainly dies.

Quality assurance of dies

Experienced inspectors provide die quality assurance through independent inspections.

They have a deep understanding of customer specifications and is able to confirm if dies are produced according to customer's needs.

05 PROJECT MANAGEMENT

Total Coordination From Order To Shipment

Project Manager System

We have introduced a project manager system as a series of contact points, from meetings held before and after receiving orders to delivery of dies to customers. We will fulfill our role of coordinating with customers to meet the needs of a wide variety of customers.

Production management system linking design and production

Based on the schedule of the customer, we have built our own production management system, which includes the phases of die design and die manufacturing. In particular, the machining schedule for each die with a large number of workpieces is managed on a piece-by-piece and hourly basis, and the system is operated in an integrated system that transcends departmental boundaries.

Delivery for Progressive Sheet Metal Dies

The delivery method for progressive sheet metal dies depends on factors like size, weight, destination, urgency, and customer requirements. Here are common delivery options:

1. Land Transportation (Truck/Freight)

Domestic Shipping:

Used for local or regional deliveries.

Common for large/heavy dies that cannot be airlifted.

Options include flatbed trucks or enclosed freight for protection.

International (Cross-Border):

For neighboring countries (e.g., US to Mexico, EU shipments).

Requires proper customs documentation.

2. Air Freight (Express Shipping)

Best for urgent deliveries or smaller dies.

Faster but more expensive than sea freight.

Used when customer needs dies quickly for production.

Airlines like DHL, FedEx, or UPS handle smaller dies; larger ones may need cargo planes.

3. Sea Freight (Ocean Shipping)

Preferred for large, heavy dies shipped internationally.

Cost-effective but slower (weeks to months).

Dies are packed in wooden crates or steel containers for protection.

Requires proper export/import documentation (HS codes, customs clearance).

4. Courier Services (DHL, FedEx, UPS)

Suitable for small dies or spare parts.

Fast delivery (3–7 days internationally).

Tracking and insurance options available.

5. Specialized Logistics (Oversized/Heavy Dies)

For extremely large dies, specialized heavy-lift transport may be needed.

Uses flat-rack containers or RO-RO (Roll-on/Roll-off) for oversized dies.

Key Considerations for Delivery:

Packaging: Dies must be securely packed in wooden crates with moisture-proofing.

Insurance: High-value dies should be insured against damage/loss.

Customs Clearance: Proper commercial invoices, packing lists, and HS codes must be prepared.

Lead Time: Sea freight takes longer; air is faster but costly.

FAQ

Q: Are you a manufacturer or trading company?

A: HT tool&die is the one-stop Progressive Sheet Metal Dies manufacturer with 24 years mould design experience and manufacturing capability .

Q: What is your company need before to submit a quotation?

A: 2D/3D CAD files , and provide the following information, such as material, monthly output, process requirements, surface treatment, equipment requirements, required precision, packing requirement etc. Because most of products are customized products of customers, we need customers to provide as detailed product information as possible, so that we can provide accurate quotation and product services.

Q: What is the free quantity of mold test sample?

A: HT Tool offers 100 free production sample services. Customers can choose to have us produce 100 samples for free at any precision stage.(The materials are provided by the customer

Q: What is the process of Progressive Sheet Metal Dies manufacturing?

A: Progressive dies are precision tools used in high-speed stamping to produce complex sheet metal parts in multiple stages. The manufacturing process involves design, machining, heat treatment, assembly, and testing. Progressive die manufacturing requires high-precision machining, heat treatment, and meticulous assembly.

Proper design and testing ensure long tool life and consistent part quality.

Would you like details on cost factors or troubleshooting common die failures? Let me know!

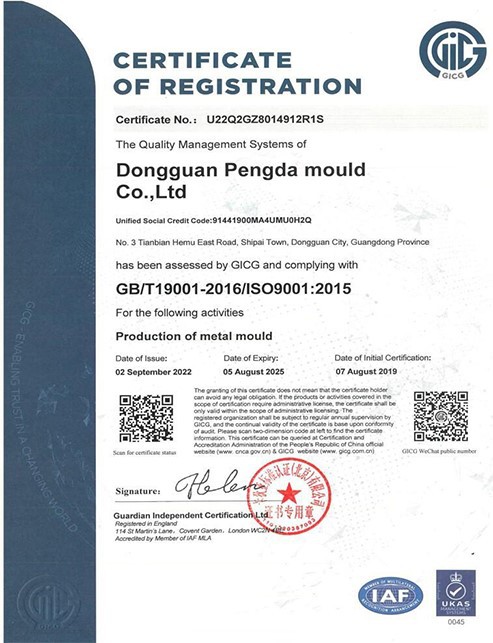

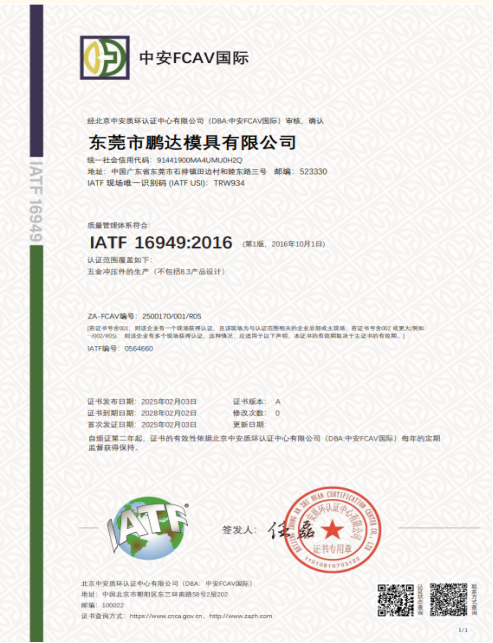

Our certficate

Hot Tags: progressive sheet metal dies, China progressive sheet metal dies manufacturers, suppliers, factory, Punch Riveting Die, Progressive Die Tooling, Electronic Components, progressive die stamping, Auto Seat Parts, metal mould air fryer

Previous

No InformationYou Might Also Like

Send Inquiry