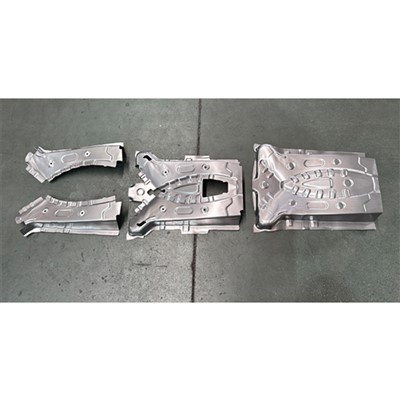

Sheet Metal Progressive Tool

Product size:2300L*800W*650H

Material:Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc.

Products Description

|

Product Name |

sheet metal progressive tool |

|

Item No. |

HTSD-003 |

|

Product size |

2300L*800W*650H |

|

Material |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Material thickness |

0.5-8mm or customized |

|

Surface treatment |

Zinc plated, powder coated, painting, polishing, brushing, chrome plating, anodizing, sandblasting, etc. |

|

Machining Equipment |

CNC,EDM,Argie Charmilles,Milling Machine,3DCMM, |

|

Professional level |

Adhering rigorously to technical specifications to uphold product strength and precision, engaging in expert negotiation on techniques, ensuring prompt production, maintaining quality assurance, conducting thorough 100% inspections, and facilitating swift and convenient shipping logistics. |

|

Process capability |

Stamping, bending, deep drawing, welding, laser cutting, CNC turning, milling,drilling, etc. |

|

Testing Facility |

Three coordinate measuring machine,Micrometer,calipers,3D scanner |

Why Choose US!

1,Our capability:

CAE Analysis:Accurate CAE analysis helps to improve parts quality and optimize progressive metal stamping transfer die and other stamping tooling process. Concurrent engineering, product design review, and early involvement can help shorten the project lead-time.This is example of our progressive metal stamping CAE simulation:

CAE simulation

3D transfer die simulation

Stamping die designing:In the tool design department, we are able to provide our customers with a full range of services. Engineers use AUTOFORM to ensure the manufacture ability of stampings and simulation (studies from cracks, wrinkles, rebound, compensation, videos, etc. are available). For complete 3D / 2D tooling design, our designers (x9) use UG software.

3D progressive metal stamping design

3D transfer die design

Project management:For each sheet metal progressive tool project, we will assign one project engineer to manage the whole procedure from concept of the very beginning to perfect completion. We have a wonderful project management team, who owns strong engineering background and good at English communication. This helps your project goes smoothly and well under control. We will keep customer updated about detail information of this project by weekly report and updated pictures. It is easy for customer to manage the project at the same time. We will provide high standard of customer service by self-improvement. Just one phone call, or an e-mail, and you'll see we are ready for you anytime.

Production cost optimization:When closely working with customers from process planning till tool designing for sheet metal progressive tool, we always spend a lot of resources and efforts on maximizing the rates of material utilization & press stroke and minimizing the tool station numbers while ensuring production stability and repeatability.

Stamping die manufacture:HT TOOL is able to create sheet metal progressive tool in-house to meet all of our customer needs. Our engineering department works with our talented staff to ensure the quality of your parts.The below chart is our machining equipment list:

|

Item No. |

Equipment |

Specification (mm) |

QTY |

|

1 |

Press Machine |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Three-in-one feeding machine |

Width 600mm,thickness 0.5- 4.5mm |

1 |

|

5 |

Three-in-one feeding machine |

Width 1200mm,thickness 0.5- 6.0mm |

1 |

|

6 |

CNC |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Surface Grinding Machine |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Manual Grinding Machine |

150*400 |

2 |

|

10 |

Vertical Drilling Machine |

ф1~32 |

3 |

|

11 |

Radial Drilling Machine |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Milling Machine |

1150*500*500 |

2 |

|

14 |

Normal Wire Cutting Machines |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Fast Wire Cutting Machines |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Stoma EDM |

300*200 |

1 |

|

19 |

3D Scanner |

650*550 |

1 |

Our Advantages:

1. More competitive and much lower tool cost for sheet metal progressive tool is available from us, we are medium size company and the cost of management will be very limited not like the large scale companies they have too much management cost on it.

2. Each of your project will be run very quickly at our companies, after customers confirmed the tools structures,we can move to next step to start the project without time waste.

3. Quality is easy to get control and to be assured.Quality is the soul of the brand, precision is the basis of the business. In order to ensure precise quality,HT Tool&Die especially sets up a quality department, which is equipped with 3D measuring instrument, 3D handy scanner projector, height measuring instrument, sclerometer and other precision measuring tools. It strictly implements the ISO 9001 quality system requirements to precisely control all tools and stamping parts. QC inspector precisely test and adequately document the appearance, dimension and hardness of all components to ensure product quality. And then they will record the result to quality control system.

Customization services: Tailoring steel sheet progressive dies according to clients' provided drawings or samples, ensuring alignment with their specific requirements.We also provide key account management.

More care about the customers:At HT tool,we provide turnkey services for each of our customer, we take your requirement as priority,and we fully guarantee customers' satisfaction from RFQ to the final tool running at customer's factory.

Hot Tags: sheet metal progressive tool, China sheet metal progressive tool manufacturers, suppliers, factory, Auto Bracket Parts, metal stator and rotor, Stamping Die, Transfer Die, stamping automotive parts, washer stamping die

You Might Also Like

Send Inquiry