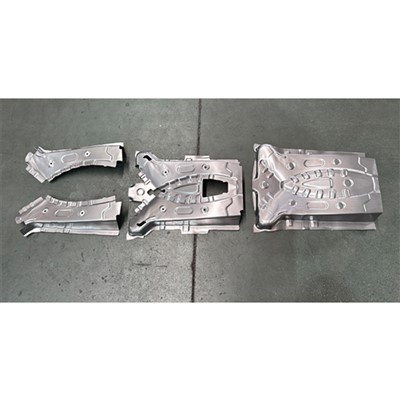

Progressive Metal Stamping

Product size:2640x935x730mm

Material:Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc.

Product Specification

|

Product Name |

Progressive metal stamping |

|

Item No. |

HTSD-001 |

|

Product size |

2640x935x730mm |

|

Material |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Material thickness |

0.5-8mm or customized |

|

Surface treatment |

Zinc plated, powder coated, painting, polishing, brushing, chrome plating, anodizing, sandblasting, etc. |

|

Machining Equipment |

CNC,EDM,Argie Charmilles,Milling Machine,3DCMM, |

|

Logo Method |

Laser engraving, CNC engraving |

|

Industry application |

Automotive,Home appliance, Electronics, Aero-space |

|

Packaging |

Wooden box or at your request |

|

Testing Facility |

Three coordinate measuring machine,Micrometer,calipers,3D scanner |

|

Production capability |

150sets annually |

Introduction of Progressive Metal Stamping

Progressive Metal Stamping Die is a metalworking method that can encompass punching, coining, bending and several other ways of modifying metal raw material, combined with an automatic feeding system.

Since additional work is done in each "station" of the die, it is important that the strip be advanced very precisely so that it aligns within a few thousandths of an inch as it moves from station to station. Bullet shaped or conical "pilots" enter previously pierced round holes in the strip to assure this alignment since the feeding mechanism usually cannot provide the necessary precision in feed length.

What benefits customers get from our products

Progressive metal stamping is a highly efficient and versatile manufacturing process used in producing various metal components, such as auto parts, electronic parts, home appliance metal parts and so on.. When it comes to progressive metal stamping, there are several benefits:

- High Efficiency: Progressive dies allow multiple operations to be performed in a single press stroke, for normal progressive stamping, production capacity can be up to 30 strokes per minute thus significantly increasing production rates compared to traditional stamping methods.With multiple operations being performed simultaneously, progressive die stamping maximizes press uptime and overall productivity, resulting in higher output rates.

- Cost-effectiveness:Despite the initial setup costs, progressive die stamping can be more cost-effective for high-volume production runs due to its speed and efficiency.So this can save a lot of production cost when customer using progressive metal stamping.

- Precision and Accuracy: Progressive dies are engineered to perform precise and consistent stamping operations, ensuring uniformity and accuracy in the produced parts.Therefore this will increase the competitiveness of stamping parts for customers.

- Complexity: Progressive metal stamping dies can accommodate complex part geometries and features, including intricate bends, forms, and perforations, making them ideal for manufacturing components with demanding design requirements.So if you have a higher request on the product, use a progressive metal stamping die to meet the requirement.

- Reduced Material Waste: The streamlined nature of progressive die stamping minimizes material waste compared to other manufacturing processes, leading to cost savings and environmental benefits.This will save the material cost for customers.

- Scalability: Progressive die stamping is easily scalable to accommodate various production volumes, making it suitable for both small-scale and large-scale manufacturing operations.Customer can adjust the production according to different quantity.

- Long service tooling life: Progressive metal stamping has required high quality raw materials and standard parts.Main materials include D2, YG15, DC53, SKD11, D2, SKH-9, and SKH-51.With high quality of raw material, this significantly increase the service life of progressive metal stamping die.The service life can be up to 2 millions strokes for the large parts.

Production process of Progressive metal stamping

Progressive metal stamping is a cutting and forming process that uses a die consisting of multiple metal stamping stations that conduct simultaneous operations on the part as it is carried through via a coiled strip. Specifically, the process follows these steps:

- Tooling creation by toolmakers. Skilled toolmakers must create the tooling, or die set, based on the needs of the specific application. Since this die set contains all the tools necessary to carry out production, the tooling does not need to be changed out between operations.

- Place the die. Once created, the die must be placed into the stamping press. The die opens as the stamping press moves up, and it closes as the stamping press moves down.

- Load the workpiece. Next, the workpiece must be placed in the die. The workpiece moves through the die while it's open, being incrementally fed into the die with each press stroke.

- Perform operations. The die can change the workpiece in various ways, such as embossing, coining, bending, cutting, and more. Once the die closes, it carries out its operation on the workpiece.

- Part ejection. Once the workpiece moves through each workstation and has taken on its final shape and size, the finished parts are ejected from the die. They can then be cut from the carrier strip.

Our Capability

CAE Analysis:Accurate CAE analysis helps to improve parts quality and optimize progressive metal stamping transfer die and other stamping tooling process. Concurrent engineering, product design review, and early involvement can help shorten the project lead-time.This is example of our progressive metal stamping CAE simulation:

Stamping die designing:In the tool design department, we are able to provide our customers with a full range of services. Engineers use AUTOFORM to ensure the manufacturability of stampings and simulation (studies from cracks, wrinkles, rebound, compensation, videos, etc. are available). For complete 3D / 2D tooling design, our designers (x9) use UG software.

Project management:For each progressive metal stamping project, we will assign one project engineer to manage the whole procedure from concept of the very beginning to perfect completion. We have a wonderful project management team, who owns strong engineering background and good at English communication. This helps your project goes smoothly and well under control. We will keep customer updated about detail information of this project by weekly report and updated pictures. It is easy for customer to manage the project at the same time. We will provide high standard of customer service by self-improvement. Just one phone call, or an e-mail, and you'll see we are ready for you anytime.

Production cost optimization:When closely working with customers from process planning till tool designing, we always spend a lot of resources and efforts on maximizing the rates of material utilization & press stroke and minimizing the tool station numbers while ensuring production stability and repeatability.

Stamping die manufacture:HT TOOL is able to creat progressive metal stamping in-house to meet all of our customer needs. Our engineering department works with our talented staff to ensure the quality of your parts.The below chart is our machining equipment list:

|

Item No. |

Equipment |

Specification (mm) |

QTY |

|

1 |

Press Machine |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Three-in-one feeding machine |

Width 600mm,thickness 0.5- 4.5mm |

1 |

|

5 |

Three-in-one feeding machine |

Width 1200mm,thickness 0.5- 6.0mm |

1 |

|

6 |

CNC |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Surface Grinding Machine |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Manual Grinding Machine |

150*400 |

2 |

|

10 |

Vertical Drilling Machine |

ф1~32 |

3 |

|

11 |

Radial Drilling Machine |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Milling Machine |

1150*500*500 |

2 |

|

14 |

Normal Wire Cutting Machines |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Fast Wire Cutting Machines |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Stoma EDM |

300*200 |

1 |

|

19 |

3D Scanner |

650*550 |

1 |

Stamping die tryout:We have Mechanical Press from 200T up to 800T

200T Mechanical Press

Max table size: 2400*840*550mm

400T Mechanical Press

Max table size: 3300*1500*750mm

800T Mechanical Press

Max table size: 4200*1800*1200mm

One-stop shop service:As a professional progressive metal stamping manufacturer in the Chinese tooling industry with solid capability and substantial capacity, HT Tool and Die offers an integral solution to customers by designing & building cold & hot-forming tools, checking fixtures and welding jigs in the global automotive industry.

The Comparison Between Stamping Dies: Simple vs. Compound die vs. Progressive metal stamping vs. Transfer Dies

|

Feature |

Simple Die |

Compound Die or Combination Die |

Progressive metal stamping |

Transfer Die |

|

Operations |

Single operation |

Multiple operations (single stroke). Very limited to design. |

Multiple operations (sequence). Slightly limited to design. Some complex drawing operations would require a transfer die |

Multiple operations (transfer between stations). Any operation process is possible. |

|

Stations |

One station |

One station |

Multiple stations |

Multiple stations |

|

Complexity |

Low |

Low to medium |

High complexity |

High complexity |

|

Mold testing and set up |

Easy |

Difficult |

Moderate. Modules reduce complexity and increase set up efficiency. |

Usually easier than progressive, but requires transfer and lifting devices that are also complex to design. |

|

Efficiency |

Very low |

Low |

Very high |

High. Slower than progressive given the required transfer operations. |

|

Cost |

Low tooling cost, high part unit cost |

Medium tooling cost, medium part unit cost |

High tooling cost, very low part unit cost |

Normally higher tooling and unit cost than progressive |

|

Production volume |

Low volume |

Medium to high volume |

High volume (appropriate for mass production) |

High volume, (appropriate for mass production) |

|

Suitability |

Simple parts |

Simple parts |

Complex parts |

Larger and/or concave parts, complex parts |

|

Material utilization rate |

Moderate to high |

Moderate to high |

Moderate. The need for pilots and carriers can reduce material utilization. A good design can highly reduce the scrap produced. |

Moderate to high |

|

Blanking operation |

1 stroke |

1 stroke |

The last operation |

The first operation |

Certification

FAQ

Q: How does progressive die stamping work?

Q: What the major types of metal stamping?

Q: What are the operations of progressive metal stamping?

Q: What are Progressive Metal Stamping Applications?

Hot Tags: progressive metal stamping, China progressive metal stamping manufacturers, suppliers, factory, Medical and Fiber Optic Parts, progressive die stamping, Other Metal Stamping Dies, Metal Stamping for the Automotive Industry, Washing Machine Die, Automotive Tooling

You Might Also Like

Send Inquiry