Q: How is HT TOOL's Automotive Progressive die unique compared to other products in the market?

A: 1. Professional team: We have an experienced team of professionals who are proficient in CAD/CAM software and simulation analysis tools, with professional background and skills in automotive progressive die design and manufacturing.

2. Customized service: We provide customized Automotive Progressive die solutions, which can be designed and manufactured according to customer's specific needs and requirements, including customized design in terms of part size, material selection and process parameters.

3. Quality Assurance: We strictly control the production process to ensure that every detail meets high standards. Our products pass strict quality control and testing to ensure that their quality and performance meet customers' expectations.

4. Comprehensive after-sales service: We provide comprehensive after-sales service, including installation and commissioning, technical support, maintenance, etc. to ensure smooth operation and long-term satisfaction of our customers when using Automotive Progressive die.

5. Equipment support: We have perfect equipments, including CNC machining equipments, press, etc., to support the design and manufacture of automotive progressive die, to ensure product quality and production efficiency.

Q: What specific automotive manufacturing needs can HT TOOL's Automotive Progressive die address?

A: Our Automotive Progressive die can meet various automotive manufacturing needs, including but not limited to the following:

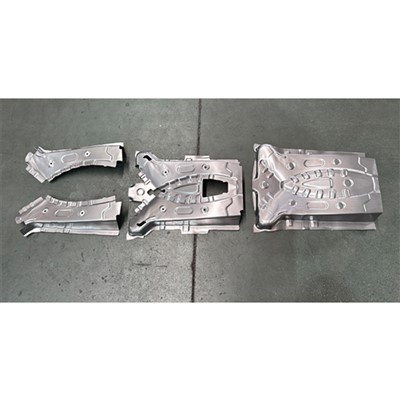

1. Component production: It can design and manufacture molds for producing automotive components, such as body structural parts, etc.

2. Chassis components: It can manufacture chassis components, such as chassis beams, chassis brackets, etc.

3. Powertrain components: It can be used to produce powertrain components for automobiles, such as engine metal brackets, etc.

Q: In the design and manufacturing process, how does our team ensure the quality and performance of Automotive Progressive die?

A: 1. Rigorous design evaluation: Our engineering team conducts in-depth assessments and analyses of each design scheme to ensure it meets the technical requirements and performance indicators specified by the customer.

2. Advanced manufacturing equipment: We have state-of-the-art CNC machining equipment capable of achieving high-precision manufacturing, ensuring the dimensional and shape accuracy of mold components.

3. Material selection: We choose high-quality materials for manufacturing to ensure the molds have excellent wear resistance, corrosion resistance, and strength, thereby enhancing their service life.

4. Strict quality control: We conduct rigorous quality control and inspections at every stage of manufacturing, including raw material inspection, process inspection, and final product inspection, to ensure compliance with quality standards at each step.

5. Simulation and testing: We use CAD/CAM software for simulation analysis to evaluate the feasibility of designs. After manufacturing, we conduct functional testing and performance validation of the molds to ensure they meet the design requirements.

6. Continuous improvement: We continually pursue technological innovation and process improvement, optimizing design and manufacturing processes to enhance the quality and performance of the molds.

Q: Does HT TOOL provide customized Automotive Progressive die solutions?

A: Yes, we offer customized Automotive Progressive die solutions. With our team's extensive experience and expertise, we can design and manufacture customized molds that meet the specific needs and requirements of our customers,helping them improve production efficiency, reduce costs, and achieve higher levels of production quality and precision.

Q: Can HT TOOL's Automotive Progressive die adapt to parts of different specifications and sizes?

A: Whether it's small parts or large parts, we can customize the design according to the customer's requirements to ensure that the mold can accurately and efficiently produce parts that meet the requirements. Our molds are flexible and adjustable, capable of accommodating production of parts with different sizes and specifications while maintaining high efficiency and stable production rates. Through our customized design and manufacturing processes, customers can obtain the most suitable Automotive Progressive die solution tailored to their specific production needs and part designs, thus achieving high-quality and efficient production.

Q: What does the after-sales service include?

A: Our after-sales service includes the following:

1. Installation and debugging service: We provide professional installation and debugging services for the Automotive Progressive die.

2. Technical support: Our technical team is available to provide support to customers, answering questions regarding the use, maintenance, and troubleshooting of the Automotive Progressive die.

3. Problem resolution: Our after-sales team is responsible for promptly responding to customer inquiries and feedback, providing corresponding solutions to ensure customer satisfaction with our products and services.

Through our comprehensive after-sales service system, we are committed to providing customers with full support and assurance, ensuring that they can fully utilize the Automotive Progressive die to achieve their production goals and ensure the long-term stable operation of the equipment.

Q: Can using Automotive Progressive die improve production efficiency?

A: Yes, using our Automotive Progressive die can significantly improve production efficiency. Here are some aspects that can contribute to increased production efficiency:

1. High-speed production: Automotive Progressive die can complete multiple operations in a single die run, reducing transfer and waiting times between operations and increasing production speed.

2. Multiple parts formed in one operation: By running the die once, multiple parts can be produced simultaneously, reducing production cycles and costs, thus enhancing production efficiency.

3. Precision machining: Our die design and manufacturing ensure high precision and consistency of parts, reducing scrap rates and improving production efficiency.

4. Automated production: Automotive Progressive die can be used in conjunction with automated equipment to achieve production automation and continuity, reducing manual intervention and improving production efficiency.

5. Reduced setup time: Our customized solutions better adapt to customer production needs, reducing setup and mold changeover times, thus enhancing production line flexibility and response speed.

Q: Does automotive progressive die comply with international standards?

A: Yes, our products comply with international standards. In the design, manufacturing, and quality control processes, we strictly adhere to international standards and industry regulations to ensure that our products meet international standards for quality, safety, and reliability. Our manufacturing processes and quality management systems conform to ISO 9001 standards.

Q: What is the design cycle for Automotive Progressive die?

A: The design cycle for Automotive Progressive die depends on various factors, including the complexity of the design, the specifications and quantity of parts, customer requirements, and the workload of the design team. Generally, the design cycle can range from several weeks to several months.

For simple designs and small quantities of parts, the design cycle may be relatively short, typically completed within a few weeks. However, for complex designs and high-volume production requirements, the design cycle may be longer, potentially taking several months. Therefore, in terms of the design cycle, we provide time estimates and schedule arrangements based on the specific needs of the customer and the project.

Q: How are orders processed?

A: Typically, the process involves the following steps:

1. Customer Requirement Confirmation: The customer provides HT TOOL with detailed information regarding product specifications, quantity, delivery time, and any other specific requirements.

2. Quotation and Negotiation: HT TOOL provides a quotation based on the information provided by the customer and negotiates with the customer on pricing, delivery terms, and other conditions to reach an agreement.

3. Order Confirmation: Once both parties agree on all details of the order, the customer confirms the order and makes a deposit payment.

4. Production and Manufacturing: HT TOOL initiates the production and manufacturing of the product according to the order requirements, which includes design, processing, assembly, and testing processes.

Q: Does HT TOOL provide training services to help customers understand how to use Automotive Progressive die correctly?

A: We will provide technical support to customers, address any issues they encounter during usage, and provide corresponding solutions.

Q: What types of automotive manufacturing processes can HT TOOL's products be used for?

A: Our products can be used for various types of automotive manufacturing processes, including but not limited to:

1. Stamping Process: Suitable for stamping processing of automotive components.

2. Coating Process: Suitable for coating processing of automotive components, including spraying, electrophoretic coating, etc., such as surface treatment of components.

Q: How is the material selection for Automotive Progressive die done?

A: Common materials used for Progressive die include tool steels (such as D2, A2, S7) and hard alloy steels (such as WC-Co alloys). We will select the most suitable material based on the specific requirements and application scenarios of the customer, ensuring the best cost-effectiveness in material selection.

Q: If provide automotive progressive die samples for testing?

A: Yes, customers can request samples from us, and we will promptly arrange for sample production and delivery to the customer for testing and evaluation. We welcome customers to request sample testing, and we will make every effort to provide satisfactory solutions to customers.

Q: Does HT TOOL's products have corrosion resistance and wear resistance?

A: We employ high-quality processes and technologies in material selection and surface treatment to ensure that our products can resist corrosion and wear during use. These characteristics enable our products to operate stably for long periods, meeting the needs of customers in various environments and working conditions.

Q: What automotive parts production is HT TOOL's Automotive Progressive die suitable for?

A: Our Automotive Progressive die is suitable for producing various automotive parts, including but not limited to the following:

1. Stamped Parts: Such as body components, metal panel parts, etc.

2. Brake System Components: Such as brake pad parts, etc.

3. Chassis Components: Such as suspension parts, etc.

Q: What is HT TOOL's pricing strategy?

A: 1. Product specifications and customization level: Prices may vary for products with different specifications and levels of customization. Generally, products with higher customization levels and more complex technical content may have relatively higher prices.

2. Order quantity and frequency: Bulk orders typically enjoy more favorable prices, and frequent customers may receive additional discounts or benefits.

3. Market competition and positioning: HT TOOL formulates reasonable pricing strategies based on market competition and its own positioning to ensure the competitiveness of its products in the market. Overall, HT TOOL provides reasonable and competitive prices based on customer needs and project requirements. Additionally, tailored discount policies may be offered according to the specific circumstances of different customers to achieve mutual benefits.

Q: Can HT TOOL provide Automotive Progressive die customer cases or references?

A: If you are interested in obtaining relevant information, please contact HT TOOL's sales team, who will be happy to provide you with the necessary details.

Q: How are customer's Automotive Progressive die customization requirements handled?

A: 1. Requirement collection and analysis: Engage in thorough communication with the customer to understand their specific technical requirements, performance indicators, application scenarios, and customization needs. Gather and analyze relevant information provided by the customer, including part dimensions, material requirements, process flows, etc.

2. Technical assessment and design: Based on the customer's requirements and information, conduct technical assessments and design. The design team utilizes CAD/CAM software for mold design, customizing the design according to the customer's specifications, including part dimensions, structural design, mold layout, etc.

3. Sample production and testing: Produce customized samples for testing and validation. Customers can evaluate the samples and provide feedback.

Q: Can HT TOOL's after-sales support respond to customer inquiries and needs in real-time?

A: Yes, our team is committed to providing efficient and timely technical support and services to ensure that customers achieve the best experience and results when using our products. Customers can contact us through various channels such as phone, email, online chat, etc., and we will respond promptly with solutions.