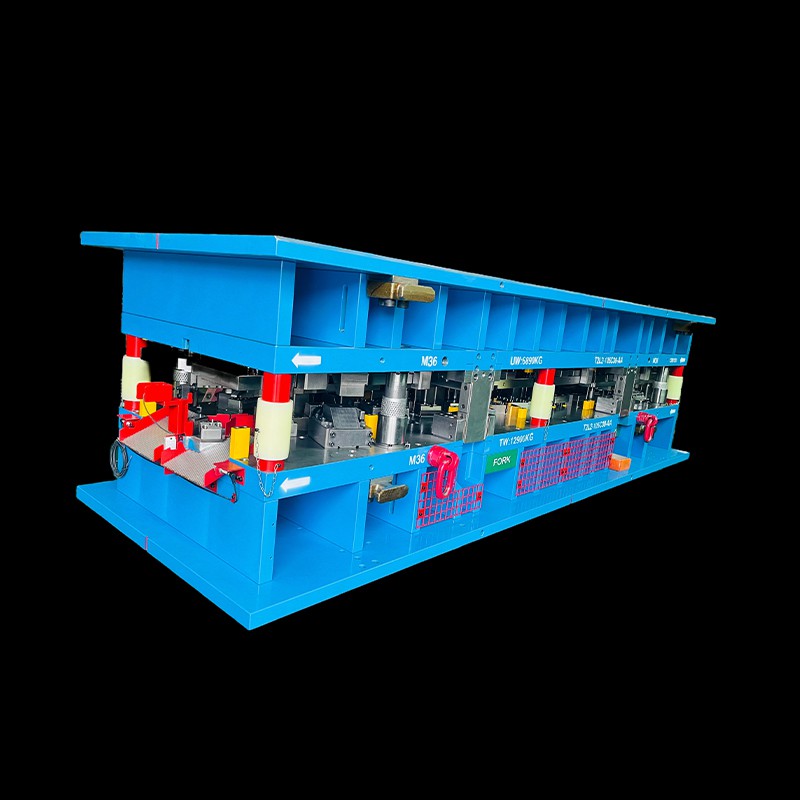

Progressive Die Manufacturing

Product size:2500L*700W*550H

Material:Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc.

Product Specification

|

Product Name |

Progressive Die Manufacturing |

|

Item No. |

HTSD-005 |

|

Product size |

2500L*700W*550H |

|

Material |

Carbon steel, stainless steel, aluminum plate, brass, copper or galvanized sheet metal etc. |

|

Material thickness |

0.5-8mm or customized |

|

Machining Process |

Milling,Grinding,Boring,CNC,EDM,WEDM,Precision Flat Milling |

|

Press try-out |

200-800T press machines |

|

Inspection |

CMM,3D laser scanner,Alloy Analyzer,Micro-Calliper,Vision Projector |

|

Forming Way |

Punching,Blanking,Piercing,Forming, Deep Drawn |

|

Precision Accuracy |

High precision machining,min.0.02 |

|

Standard Component |

MISUMI,PUNCH,FIBRO,DAYTON,DANLY etc. |

|

Surface treatment |

Zinc plated, powder coated, painting, polishing, brushing, chrome plating, anodizing, sandblasting, etc. |

|

Machining Equipment |

CNC,EDM,Argie Charmilles,Milling Machine,3DCMM, |

|

Logo Method |

Laser engraving, CNC engraving |

|

Industry application |

Automotive,Home appliance, Electronics, Aero-space |

|

Packaging |

Wooden box or at your request |

|

Testing Facility |

Three coordinate measuring machine,Micrometer,calipers,3D scanner |

|

Production capability |

150sets annually |

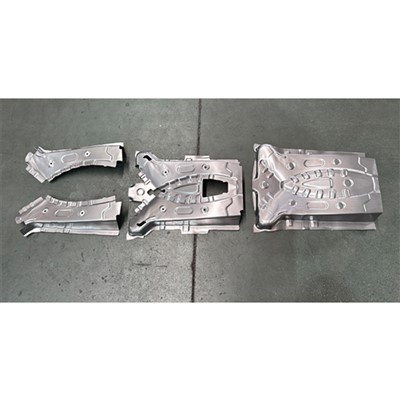

Related Products for Progressive Die Manufacturing

Our services

Our advantages

1)We adhere to total solution service:

product design optimization→ stamping die design→ stamping die manufacturing→ stamping die debugging→ product inspection→ die specification manual sharing→ after-sales support.

2)3D and CAD/CAM/CAE design

3)More than 10 stamping tooling design engineers

4)During nearly 20 years of development, Hiparter insists on providing high-standard and high-quality stamping dies and support.

2.Progressive Die Manufacturing Capacity

1)Stamping die machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

3. Progressive Die Manufacturing Production Capacity

1)200T~800T press machines for try out

2)Equipped with Press machine and hydraulic machine

3)Material feeder for progressive die 2 sets

4)Experienced technology engineers and well trained workers

5)Almost all the stamping die trial completed in-house.

4. Stamping Die

Quality Control Capacity

1)Full equiped with inspection machines, including CMM, projector, 3D scanner, Blue scanner, White scanner, Alloy analyzer, etc.

2)CMM inspection for the die cores and inserts.

3)Inspection report for stamping dies and stamping parts

4)In order to control the quality of the stamping dies, we have a strict quality control mechanisms.

5. Progressive Die Manufacturing

Delivery Control Capacity

1)2~6 weeks lead time

2)Update stamping die building progress to customer weekly, control project progress to ensure project schedule

3)Exported to over 30 counties

4)With more than 10 years of import and export experience, cooperate with powerful logistics companies and major express

companies, to ensure smooth export and delivered to customers asap.

Our equipment lists

|

Item No. |

Equipment |

Specification (mm) |

QTY |

|

1 |

Press Machine |

800 T(4200*1900*1200) |

1 |

|

2 |

400 T (3300*1500*750) |

1 |

|

|

3 |

200 T (2400*840*550) |

1 |

|

|

4 |

Three-in-one feeding machine |

Width 600mm,thickness 0.5- 4.5mm |

1 |

|

5 |

Three-in-one feeding machine |

Width 1200mm,thickness 0.5- 6.0mm |

1 |

|

6 |

CNC |

2500*1700*1000 |

1 |

|

1100*650*750 |

1 |

||

|

800*500*550 |

3 |

||

|

7 |

Surface Grinding Machine |

1000*600 |

1 |

|

8 |

800*400 |

1 |

|

|

9 |

Manual Grinding Machine |

150*400 |

2 |

|

10 |

Vertical Drilling Machine |

ф1~32 |

3 |

|

11 |

Radial Drilling Machine |

¢1~32 |

1 |

|

12 |

¢1~50 |

1 |

|

|

13 |

Milling Machine |

1150*500*500 |

2 |

|

14 |

Normal Wire Cutting Machines |

800*630 |

1 |

|

15 |

500*400 |

4 |

|

|

16 |

Fast Wire Cutting Machines |

800*500 |

1 |

|

17 |

500*400 |

1 |

|

|

18 |

Stoma EDM |

300*200 |

1 |

|

19 |

3D Scanner |

650*550 |

1 |

Package and delivery

To guarantee the delivery of Progressive Die Manufacturing for molds

With rich experience in exporting, we choose reasonable packaging for you to reduce the shipping risk. For the packaging of stamping die, the stamping dies are vacuum packed in aluminum film bag first, fastened by metal packing tape, and then packed in wooden cases.

Of course, we can also make the packing following customers' requirement.

Our business partner

FAQ

Hot Tags: progressive die manufacturing, China progressive die manufacturing manufacturers, suppliers, factory, Machined Parts, Home Appliance Die, Self clinching Nuts, Prototype Die, metal mould air fryer, Punch Riveting Die

You Might Also Like

Send Inquiry