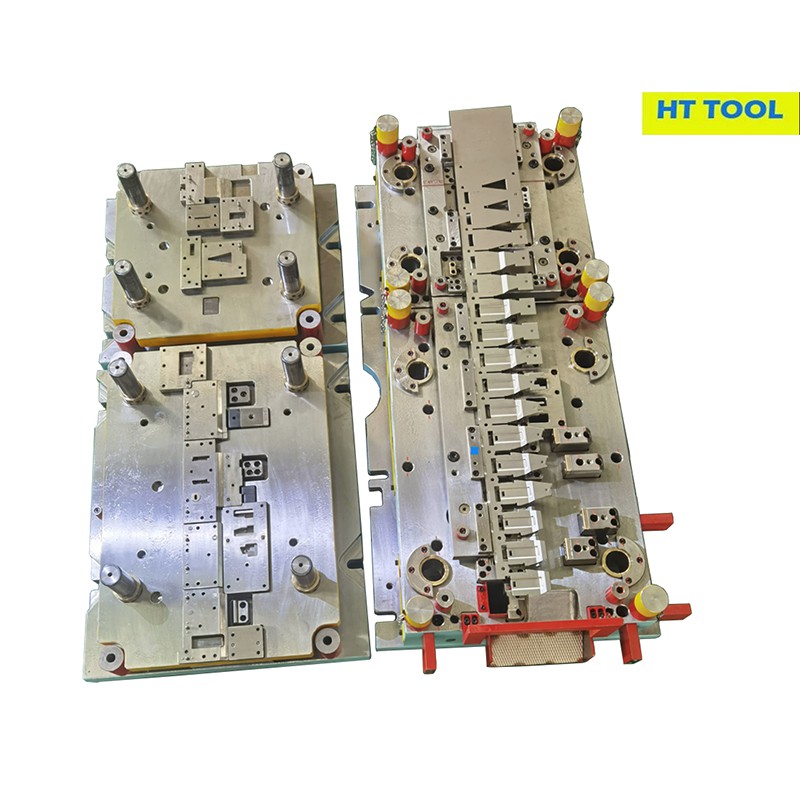

Jig Checking Fixture

Product size:98*49*37mm

Material:Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless steel, Steel Alloys

Product Specification

|

Product Name |

jig checking fixture |

|

Item No. |

HTCK-004 |

|

Product size |

98*49*37mm |

|

Material |

Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless steel, Steel Alloys |

|

Accuracy |

0.005-0.1 mm or at your request |

|

Color |

Anodized, aluminum colors, black or individual parts can be customized to customer request |

|

Surface treatment |

Sand blasting, heat treatment, Sand blasting, heat treatment, etc |

|

Machining Equipment |

CNC,EDM,Argie Charmilles,Milling Machine,3DCMM, |

|

Logo Method |

Laser engraving, CNC engraving |

|

Usage |

Auto Checking Fixture |

|

Packaging |

Wooden box or at your request |

|

Testing Facility |

Three coordinate measuring machine,Micrometer,calipers |

|

Lead time |

15-20days after structure approved |

Jig Checking fixture Introduction

HT Tool&Die has supplied a number of jig checking fixture for the automotive industries. The abilities of our in-house jig checking fixture and tool design facilities enable simple jigs and more complex fixtures to be designed to suit the customer's requirement.Made in strict adherence to industry norms and using best quality raw materials, our extensive range of jigs and fixtures are available in all sizes, shapes and material as per client's requirement.

Jig Checking Fixture and Check Gauge for High Precision Automotive Fitting Parts

It is used to locate assembly parts. It is used to quickly and intuitively check holes,mating surfaces, contours and other main features with a hand gauge to verify whether the product is qualified.

It has the following advantages

- Affordable price

- Excellent after-sales service

- High positioning accuracy

- High product quality and shipping efficiency

Our Company Capacity

Engineering Capacity

Competitive Advantages

Software Automation

UG secondary development automatic design increases the efficiency by more than 30% ;

Design Standardization.

90% components are standardized during the designing stage in order to shorten lead-time and reduce cost;

Customer Requirement & Satisfaction.

To better understand customer's specification and requirement, tech review in person and local support on site are available for big.

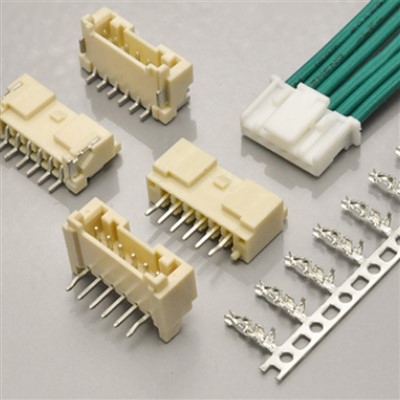

Production Capacity

- 80-800T mechanical press machine

- tooling manufacturing capacity:10sets(15tons of tooling)

- Materials:Steel,Stainless Steel,Aluminum,Copper,Brass

- 30 days fast mould delivery

- OEM customized services for customers

Quality Control Capacity

- 8persons full-time quality control in department

- CMM measuring machine

- 3D blue light scanner

- ISO9001 quality management system certification

- R&R report and SGS report are available

Delivery Control Capacity

- Each order is planned in advance

- Weekly report or timeline is provided each week

- If there is any abnormality in production,we will take measures at once.

- In case of delay in delivery,we will bear the cost of logistics

Certification

FAQ

Q: What is a jig checking fixture?

Q: How to design a jig checking fixture?

Q: What is the main purpose of a jig checking fixture?

Q: What is the general principle of jig and fixture?

Q: Why are jigs and fixtures important?

Hot Tags: jig checking fixture, China jig checking fixture manufacturers, suppliers, factory, Metal Stamping for the Appliance Industry, Stamping Die, Steel Sheet Progressive Die, casting die progressive, Transfer Die, New Energy Vehicles Parts

Previous

Auto Checking FixtureYou Might Also Like

Send Inquiry