Strip Layout Design

Products Description

|

Product Name |

Strip layout design |

|

Item No. |

HTSL-003 |

|

Product size |

110*40*1.2mm |

|

Material |

Stainless steel,aluminum |

Progressive strip layout Introduction

During strip layout development, engineers have to define the type of stamping operations required for the part production, the sequence of operations, the required number of stations and the operations to be performed at each station of progressive die.

Why choose Progressive strip layout from HT tool&die

CAE Analysis:

Accurate CAE analysis helps to improve parts quality and optimize tooling process. Concurrent engineering, product design review, and early involvement can help shorten the project lead-time.

3D Strip Layout Design--Progressive die

3D Strip Layout Design--Transfer Die

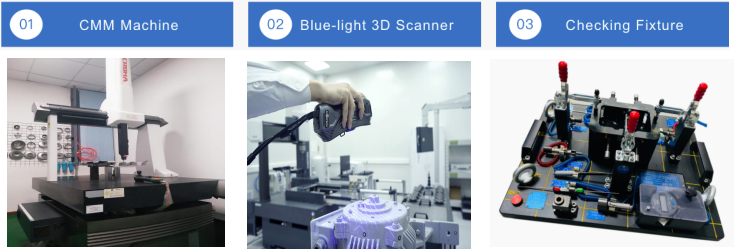

Strict Quality Control:

Quality is the soul of the brand and is the basis of company business development. In order to ensure precise quality, HT Tool&Die especially sets up a quality department, which is equipped with 3D measuring instrument, 3D handy scanner projector, height measuring instrument, and other precision measuring tools. It strictly implements the ISO 9001 quality system requirements to precisely control all tools and stamping parts. QC inspector precisely test and adequately document the appearance, dimension and hardness of all components to ensure product quality. And then they will record the result to quality control system.

We are committed to our implementation of the zero-defect quality management philosophy. This quality sense has been implemented on each process. We also have very strict supplier verification system, and we execute the regular audit to assure the best quality raw materials. Only qualified suppliers can be our cooperators.

Our factory:

HT TOOL & die is situated in Dongguan, known as the industrial hub of China, and was established in 2016. Specializing in hardware stamping dies and designs for automotive and electronics industries. Spanning across a 3,000 square meter standardized facility, we offer customers comprehensive hardware stamping die solutions and top-notch after-sales service.

HT TOOL & die boasts a complete array of processing and production equipment, enabling substantial production and processing capacity. Our primary focus lies in the production of progressive die stamping, progressive die casting, transfer die stamping and single die stamping. We aim to deliver metal stamping dies that are both reliable in performance and cost-effective, thereby facilitating less labor-intensive, cost-saving, and efficient production for our customers.

Certification

Hot Tags: strip layout design, China strip layout design manufacturers, suppliers, factory, Precision Stamped Parts, Small Appliance Parts, Electronic Components, Stamping Parts, Auto Seat Parts, casting die progressive

Previous

Strip LayoutYou Might Also Like

Send Inquiry