Can automotive tooling be customized? This is a question that many in the automotive industry often ponder. As a leading automotive tooling supplier, I am here to shed light on this topic and share insights based on our extensive experience in the field.

Automotive tooling encompasses a wide range of equipment and components used in the manufacturing process of vehicles. From stamping dies to machining tools, these items play a crucial role in ensuring the quality and efficiency of automotive production. Customization in automotive tooling has become increasingly important as the automotive industry continues to evolve, with new designs, materials, and technologies emerging regularly.

The Need for Customization in Automotive Tooling

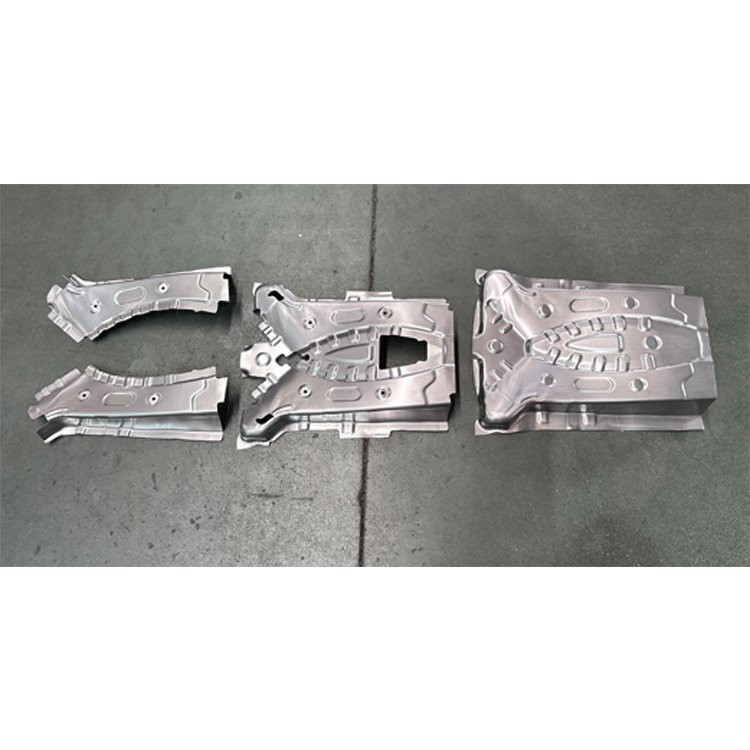

The automotive industry is highly competitive, and manufacturers are constantly looking for ways to differentiate their products. Customized automotive tooling allows manufacturers to create unique parts and components that meet specific design requirements. For example, a car manufacturer may want to develop a new model with a distinctive body shape. In this case, customized Casting Progressive Die can be designed to produce the required body panels with precision and accuracy.

Moreover, as the demand for lightweight and fuel - efficient vehicles grows, the use of new materials such as aluminum and high - strength steel has become more prevalent. These materials often require specialized tooling to be processed effectively. Customized tooling can be tailored to handle the unique properties of these materials, ensuring proper forming, cutting, and assembly processes.

In addition to design and material considerations, customization in automotive tooling can also enhance production efficiency. By optimizing the tooling design for a specific manufacturing process, manufacturers can reduce cycle times, minimize waste, and improve overall productivity. For instance, Progressive Metal Stamping is a process that can be customized to produce multiple parts in a single operation, significantly increasing the production rate.

Challenges in Customizing Automotive Tooling

While the benefits of customized automotive tooling are clear, there are also several challenges associated with the customization process. One of the main challenges is cost. Developing customized tooling often requires significant upfront investment in research, design, and manufacturing. This includes the cost of advanced CAD/CAM software, specialized machinery, and skilled labor. For small and medium - sized automotive manufacturers, these costs can be a major barrier to adopting customized tooling solutions.

Another challenge is the time required for customization. Designing and manufacturing customized tooling is a complex and time - consuming process. It involves multiple stages, such as concept development, prototyping, testing, and refinement. Delays in any of these stages can have a significant impact on the production schedule of the automotive products. Therefore, it is essential to have a well - planned and coordinated project management strategy to ensure timely delivery of the customized tooling.

Quality control is also a critical challenge in customized automotive tooling. Since each customized tool is unique, it is necessary to establish strict quality control measures to ensure that the tooling meets the required specifications. This includes conducting thorough inspections during the manufacturing process and performing comprehensive testing before the tooling is put into production.

Our Approach as an Automotive Tooling Supplier

As an automotive tooling supplier, we have developed a comprehensive approach to address the challenges of customization while maximizing the benefits for our customers. Our team of experienced engineers and designers uses state - of - the - art CAD/CAM technology to create detailed 3D models of the customized tooling. This allows us to visualize the design, identify potential issues, and make necessary adjustments before the manufacturing process begins.

We also have a well - established supply chain management system that enables us to source high - quality materials at competitive prices. By working closely with our suppliers, we can ensure the timely availability of materials, reducing the overall lead time for customization.

In terms of cost, we offer flexible pricing options to our customers. We understand that different customers have different budgets and requirements, and we strive to provide cost - effective solutions without compromising on quality. For example, we may suggest alternative materials or manufacturing processes that can achieve similar results at a lower cost.

Quality control is at the core of our business. We have a dedicated quality control team that conducts regular inspections and tests throughout the manufacturing process. We also use advanced metrology equipment to verify the accuracy and precision of the customized tooling. This ensures that our customers receive tooling that meets or exceeds their expectations.

Case Studies

To illustrate the effectiveness of our customized automotive tooling solutions, let's look at a few case studies.

Case Study 1: A major automotive manufacturer approached us with a requirement for a new Automotive Progressive Die to produce a complex car body part. The part had a unique shape and required high precision in the stamping process. Our team of engineers worked closely with the customer to understand their design requirements and developed a customized progressive die. Through the use of advanced simulation software, we optimized the die design to reduce the number of operations and improve the overall production efficiency. The final die was delivered on time and met all the quality requirements, resulting in a significant increase in the customer's production rate.

Case Study 2: Another customer was looking for a solution to process a new aluminum alloy for their vehicle's engine components. The new material had different mechanical properties compared to traditional steel, and existing tooling was not suitable for its processing. We designed and manufactured customized machining tools specifically for this aluminum alloy. Our tools were able to achieve high - quality surface finishes and tight tolerances, which were crucial for the performance of the engine components. As a result, the customer was able to successfully integrate the new material into their production process, enhancing the performance and fuel efficiency of their vehicles.

Conclusion

In conclusion, automotive tooling can indeed be customized, and the benefits of customization are substantial. Customized tooling allows automotive manufacturers to create unique products, handle new materials, and improve production efficiency. However, there are challenges such as cost, time, and quality control that need to be addressed.

As an automotive tooling supplier, we are committed to providing our customers with high - quality customized tooling solutions. Our expertise, advanced technology, and customer - centric approach enable us to overcome the challenges of customization and deliver value - added products.

If you are an automotive manufacturer looking for customized tooling solutions, we invite you to contact us for a consultation. Our team of experts will work closely with you to understand your specific requirements and develop the best tooling solutions for your production needs.

References

- "Automotive Tooling Technology: Design, Manufacturing, and Applications" by John Smith

- "Advanced Manufacturing Processes in the Automotive Industry" by Mary Johnson

- Industry reports from leading automotive research institutions