Hey there! As a single casting die supplier, I know firsthand how crucial it is to transport these hefty pieces of equipment safely. A single casting die is no small fry; it's a valuable asset that can cost a pretty penny. Messing up the transportation can lead to damage, delays, and a whole lot of headaches. So, in this blog, I'm gonna share some tips on how to transport a single casting die safely.

1. Pre - Transport Planning

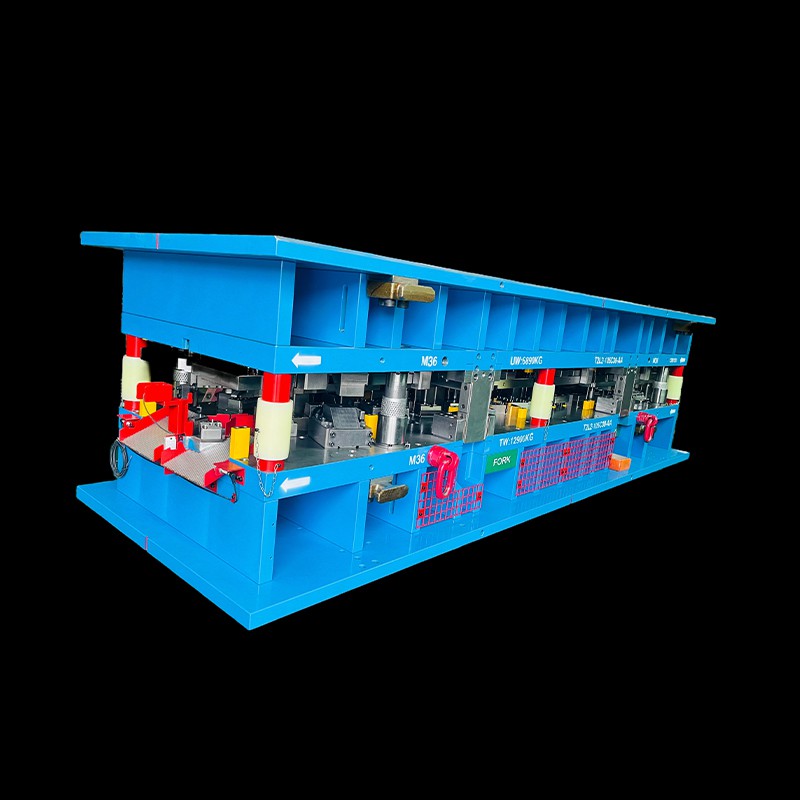

Before you even think about moving that die, you need to do some serious planning. First off, measure the die. You gotta know its exact dimensions, weight, and center of gravity. This info is vital for choosing the right transportation method and equipment. For instance, if the die is super heavy or oddly shaped, you might need specialized machinery to lift and move it.

Next, check the destination. Is the place where the die will end up ready to receive it? You need to ensure there's enough space for unloading and that the floor can support the weight. If there are any obstacles or tight spaces, you'll need to plan around them.

Also, look into the route. Are there any low bridges, narrow roads, or weight - restricted areas? You don't want to get stuck halfway through the journey because you didn't do your homework. You can use mapping tools to find the best route, taking into account all these factors.

2. Packaging

Proper packaging is a must when it comes to transporting a single casting die. The die should be wrapped in a protective material, like bubble wrap or foam padding, to prevent scratches and minor dents. This layer acts as a shock absorber during transit.

After that, place the die in a custom - made crate. The crate should be sturdy enough to withstand the rigors of transportation. It should be made of high - quality wood or metal, depending on the size and weight of the die. The crate should also have reinforcement at the corners and edges to provide extra protection.

Label the crate clearly. Write down the die's dimensions, weight, and handling instructions. This will help the handlers know how to deal with the crate properly and reduce the risk of damage.

3. Loading

Loading the die onto the transportation vehicle is a critical step. You need to use the right equipment, such as cranes or forklifts. Make sure the equipment is in good working condition and that the operators are well - trained.

When lifting the die, attach the lifting equipment securely to the die's lifting points. These points are specifically designed for lifting, and using them correctly will prevent the die from tipping or falling during loading.

Once the die is on the vehicle, secure it properly. Use straps or chains to tie the die down to the vehicle's deck. The straps should be tight enough to prevent the die from moving during transit but not so tight that they damage the die.

4. Transportation Method

Choosing the right transportation method depends on several factors, such as the distance, the size and weight of the die, and the urgency of the delivery.

For short distances, a flatbed truck might be a good option. It's relatively easy to load and unload, and you can keep an eye on the die during the journey. However, for long - distance transportation, you might consider using a containerized shipment. Containers offer more protection from the elements and are less likely to be damaged during transit.

If you're transporting the die overseas, you'll need to use a shipping vessel. Make sure to work with a reliable shipping company that has experience in transporting heavy and valuable equipment. They'll handle all the customs clearance and other paperwork for you.

5. Monitoring

During transportation, it's a good idea to monitor the die's condition. You can use tracking devices to keep an eye on the location of the shipment. Some advanced tracking devices can also monitor factors like temperature, humidity, and vibration.

If there are any sudden changes in these factors, it could indicate that there's a problem with the shipment. For example, excessive vibration could mean that the die is not properly secured, and high humidity could cause corrosion.

6. Unloading

When the die arrives at its destination, unloading should be done with the same care as loading. Use the appropriate equipment and follow the same safety procedures.

Once the die is unloaded, inspect it for any damage. If you find any issues, document them immediately and contact the transportation company and your insurance provider.

7. Post - Transport Inspection

After the die has been installed at its final location, do a thorough inspection. Check for any signs of damage that might not have been obvious during the initial inspection. Make sure the die is functioning properly before you start using it.

Why Choose Us as Your Single Casting Die Supplier

As a single casting die supplier, we're not just about selling you a die. We're committed to providing you with a complete solution, including safe transportation. We have years of experience in handling and transporting single casting dies, and we know all the tricks of the trade.

We work with a network of reliable transportation partners who share our commitment to safety. Whether you need a die transported across town or across the ocean, we've got you covered.

We also offer a range of related products and services. If you're interested in other types of dies, like Progressive Die Manufacturing, Sheet Metal Progressive Tool, or Sheet Metal Stamping Dies, we can help you with that too.

If you're in the market for a single casting die or need to transport one safely, don't hesitate to get in touch. We're here to answer your questions and help you find the best solution for your needs.

References

- "Heavy Equipment Transportation Handbook"

- Industry best practices from die manufacturing and transportation experts