As a seasoned Punch Riveting Die supplier, I understand the critical role that proper alignment plays in the performance and longevity of these essential tools. Incorrect alignment can lead to a host of issues, including poor rivet quality, premature die wear, and even production downtime. In this blog post, I'll share some practical tips on how to adjust the alignment of a punch riveting die effectively.

Understanding the Basics of Punch Riveting Die Alignment

Before diving into the adjustment process, it's important to have a clear understanding of what alignment means in the context of punch riveting dies. Alignment refers to the precise positioning of the punch and die components to ensure that the rivet is inserted accurately into the workpiece. This involves aligning the punch with the die cavity, as well as ensuring that the die is properly seated and secured in the press.

There are several factors that can affect the alignment of a punch riveting die, including:

- Machine Wear: Over time, the components of the press and die can wear down, leading to misalignment.

- Improper Installation: If the die is not installed correctly, it can cause alignment issues.

- Workpiece Variations: Differences in the thickness, material, or shape of the workpiece can affect the alignment of the die.

- Operator Error: Incorrect operation of the press or die can also lead to alignment problems.

Tools and Equipment Needed for Alignment

To adjust the alignment of a punch riveting die, you'll need the following tools and equipment:

- Dial Indicator: A dial indicator is used to measure the alignment of the punch and die components.

- Feeler Gauges: Feeler gauges are used to measure the clearance between the punch and die.

- Torque Wrench: A torque wrench is used to tighten the bolts and nuts that secure the die in place.

- Shims: Shims are thin pieces of metal or plastic that can be used to adjust the alignment of the die.

- Cleaning Supplies: Cleaning supplies, such as a brush and solvent, are used to clean the die and press components.

Step-by-Step Guide to Adjusting the Alignment of a Punch Riveting Die

The following is a step-by-step guide to adjusting the alignment of a punch riveting die:

- Prepare the Press and Die: Before starting the alignment process, make sure the press is turned off and the die is clean and free of debris. Remove any old shims or spacers from the die.

- Install the Die: Install the die in the press according to the manufacturer's instructions. Make sure the die is properly seated and secured in place using the appropriate bolts and nuts.

- Check the Punch and Die Alignment: Use a dial indicator to check the alignment of the punch and die components. Place the dial indicator on the punch and measure the distance between the punch and the die cavity. Adjust the position of the punch as needed to ensure that it is centered in the die cavity.

- Check the Clearance: Use feeler gauges to check the clearance between the punch and die. The clearance should be uniform around the entire circumference of the punch. If the clearance is too large or too small, adjust the position of the punch or die as needed.

- Adjust the Die Height: Use shims to adjust the height of the die. Place the shims between the die and the press bed to raise or lower the die as needed. Make sure the die is level and parallel to the press bed.

- Tighten the Bolts and Nuts: Once the alignment is correct, use a torque wrench to tighten the bolts and nuts that secure the die in place. Make sure the bolts and nuts are tightened to the manufacturer's specifications.

- Test the Die: After the alignment is adjusted and the bolts and nuts are tightened, test the die by running a few sample parts. Check the quality of the rivets and make sure the die is operating smoothly. If there are any issues, repeat the alignment process until the die is working properly.

Tips for Maintaining Proper Alignment

In addition to adjusting the alignment of the punch riveting die, it's important to take steps to maintain proper alignment over time. Here are some tips for maintaining proper alignment:

- Regular Maintenance: Perform regular maintenance on the press and die to prevent wear and tear. This includes cleaning the die, lubricating the moving parts, and checking the alignment regularly.

- Proper Installation: Make sure the die is installed correctly and securely in the press. Follow the manufacturer's instructions carefully and use the appropriate tools and equipment.

- Operator Training: Provide proper training to the operators who will be using the punch riveting die. Make sure they understand the importance of proper alignment and how to operate the die safely and effectively.

- Workpiece Quality Control: Implement a quality control system to ensure that the workpieces are consistent in thickness, material, and shape. This will help to prevent alignment issues caused by workpiece variations.

Conclusion

Adjusting the alignment of a punch riveting die is a critical step in ensuring the quality and performance of the die. By following the steps outlined in this blog post and taking steps to maintain proper alignment over time, you can minimize the risk of issues and increase the lifespan of your punch riveting die.

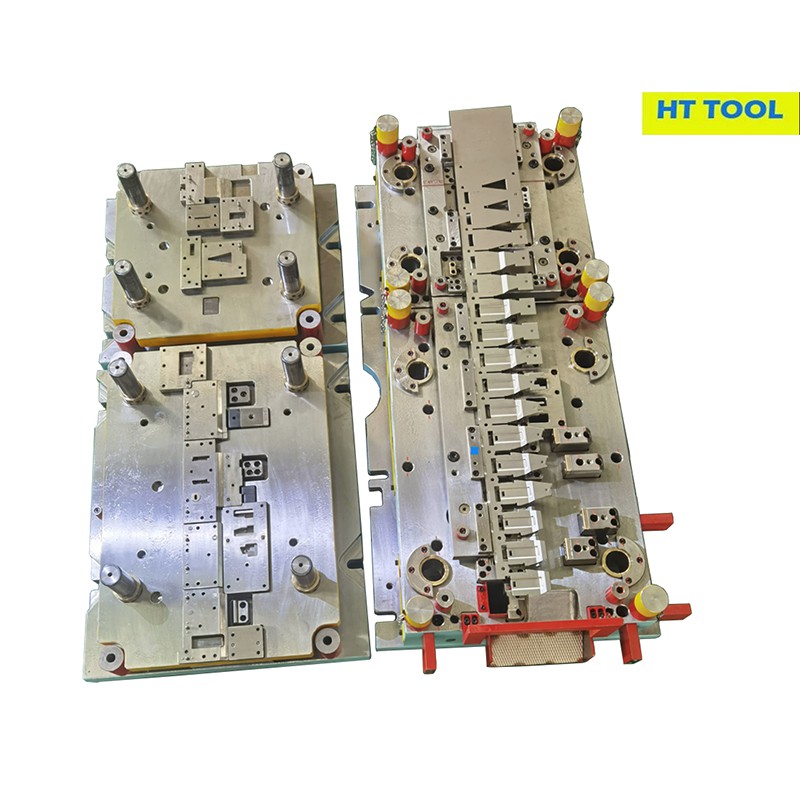

If you're in the market for high-quality Progressive Sheet Metal Dies, Furniture Hardware Stamping Die, or Metal Stamping Tool And Die, look no further. We are a leading supplier of punch riveting dies and other metal stamping tools and dies. Our products are designed to meet the highest quality standards and are backed by our commitment to customer satisfaction.

If you have any questions or would like to discuss your specific needs, please don't hesitate to contact us. We look forward to working with you to find the perfect solution for your punch riveting die requirements.

References

- "Metal Stamping Die Design and Manufacturing Handbook" by John A. Schey

- "Punching and Forming Handbook" by Peter Merz

- "Die Design Handbook" by Society of Manufacturing Engineers