As a supplier of Prototype Die, I understand the critical role that surface quality plays in the functionality and aesthetics of a prototype die. A high - quality surface finish not only enhances the visual appeal but also improves the die's performance, durability, and the quality of the parts it produces. In this blog, I will share some effective strategies to improve the surface quality of a prototype die.

Material Selection

The choice of material for the prototype die is the first and most fundamental step in achieving a good surface quality. High - quality tool steels, such as D2, A2, or H13, are commonly used for prototype dies due to their excellent hardness, wear resistance, and machinability. These materials can withstand the high stresses and temperatures during the stamping or forming process, reducing the likelihood of surface damage.

When selecting the material, it is essential to consider the specific requirements of the application. For example, if the die will be used for high - volume production, a more wear - resistant material may be required. On the other hand, if the die is for a low - volume prototype, a less expensive but still suitable material can be chosen. Additionally, the material should be free from internal defects, such as porosity or inclusions, which can negatively affect the surface finish.

Precision Machining

Precision machining is crucial for achieving a smooth and accurate surface on the prototype die. Computer Numerical Control (CNC) machining is the preferred method for machining prototype dies, as it offers high precision and repeatability. During the machining process, the cutting tools should be carefully selected and maintained to ensure a clean cut and minimize surface roughness.

The cutting parameters, such as cutting speed, feed rate, and depth of cut, also need to be optimized. A high cutting speed can reduce the cutting force and improve the surface finish, but it may also cause tool wear. A proper feed rate ensures that the cutting tool removes the material evenly, while an appropriate depth of cut prevents excessive material removal and surface damage.

In addition to CNC machining, electrical discharge machining (EDM) can be used for complex shapes or hard materials. EDM uses electrical discharges to remove material, resulting in a very smooth surface finish. However, it is a relatively slow process and may be more expensive than CNC machining.

Heat Treatment

Heat treatment is an important step in improving the surface quality of a prototype die. It can enhance the hardness, strength, and wear resistance of the die material, which in turn improves the surface finish. Common heat treatment processes for prototype dies include quenching, tempering, and nitriding.

Quenching involves heating the die to a high temperature and then rapidly cooling it in a quenching medium, such as oil or water. This process increases the hardness of the die material but may also cause internal stresses. Tempering is then performed to relieve these stresses and improve the toughness of the material.

Nitriding is a surface - hardening process that introduces nitrogen into the surface of the die. It forms a hard nitride layer, which improves the wear resistance and corrosion resistance of the die surface. Nitriding can also reduce friction, resulting in a smoother surface finish during the stamping or forming process.

Surface Finishing Processes

After machining and heat treatment, various surface finishing processes can be applied to further improve the surface quality of the prototype die. Polishing is one of the most common surface finishing methods. It uses abrasive materials to remove small amounts of material from the die surface, resulting in a smooth and shiny finish. Polishing can be done manually or using automated polishing machines, depending on the complexity of the die shape and the required surface finish.

Electropolishing is another effective surface finishing process. It uses an electrochemical reaction to remove material from the surface of the die, resulting in a very smooth and uniform finish. Electropolishing can also improve the corrosion resistance of the die surface.

Coating is also a popular way to enhance the surface quality of a prototype die. Coatings such as titanium nitride (TiN), titanium carbonitride (TiCN), and diamond - like carbon (DLC) can provide excellent wear resistance, low friction, and improved corrosion resistance. These coatings can be applied using physical vapor deposition (PVD) or chemical vapor deposition (CVD) techniques.

Inspection and Quality Control

Inspection and quality control are essential to ensure that the surface quality of the prototype die meets the required standards. Non - destructive testing methods, such as ultrasonic testing and magnetic particle testing, can be used to detect internal defects in the die material. Surface roughness measurement is also crucial to evaluate the smoothness of the die surface. Profilometers or optical surface analyzers can be used to measure the surface roughness parameters, such as Ra (average roughness) and Rz (maximum height of the profile).

In addition to surface roughness measurement, visual inspection should be carried out to check for any visible defects, such as scratches, cracks, or uneven surfaces. Any defects found during the inspection process should be corrected immediately to ensure the quality of the prototype die.

Maintenance and Care

Proper maintenance and care of the prototype die are necessary to maintain its surface quality over time. After each use, the die should be cleaned thoroughly to remove any debris, lubricants, or metal chips. A clean die surface reduces the risk of corrosion and wear.

Regular inspection of the die surface should also be carried out during its service life. Any signs of wear or damage should be addressed promptly. Minor surface damage can be repaired by polishing or re - coating, while more severe damage may require re - machining or replacement of the die.

As a Prototype Die supplier, we are committed to providing high - quality prototype dies with excellent surface quality. Our team of experts has extensive experience in material selection, precision machining, heat treatment, and surface finishing processes. We also have strict quality control measures in place to ensure that every prototype die meets the highest standards.

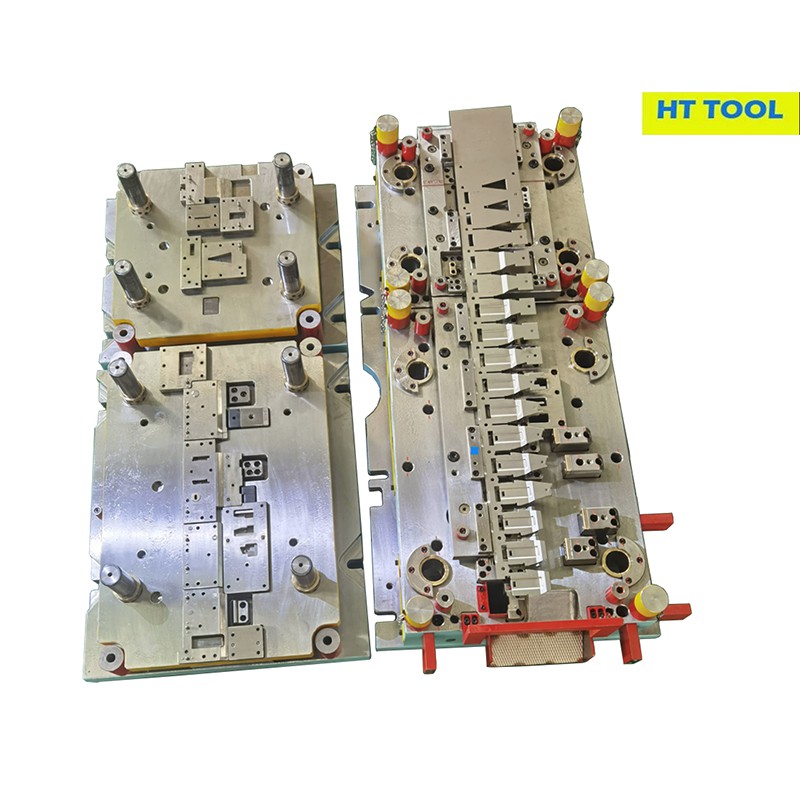

If you are looking for a reliable Prototype Die supplier, we would be glad to assist you. Whether you need a Compound Tool And Progressive Tool, a Prototype Die, or a Furniture Hardware Stamping Die, we can provide customized solutions to meet your specific requirements. Please feel free to contact us for more information and to start a procurement negotiation.

References

- Kalpakjian, S., & Schmid, S. R. (2008). Manufacturing Engineering and Technology. Pearson Prentice Hall.

- Dieter, G. E. (1988). Mechanical Metallurgy. McGraw - Hill.

- ASM Handbook Committee. (1990). ASM Handbook: Volume 4, Heat Treating. ASM International.