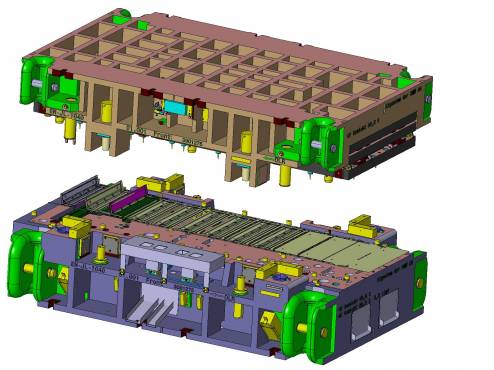

With the increasing wage of workers in the stamping industry, it is super crucial to reduce the labor cost and production cost for metal stamping manufacturers. The progressive die metal stamping is the most regular happened, It's a good way to establish a low-cost and high efficiency automation stamping production line by building progressive die. However, the progressive die requires high precision and complicated components,it is necessary to pay attention to the problems in the design process. this will require high efficient design solutions, which is mainly manifested in the followings:

1,When there are more holes punch,the length of upper die should not be too large.

For stamping die with multi upper die,build different height upper die according to the different sizes as stepped way,this can avoid the max.value of the punch pressure of the upper die created in one time thus effectively reduce the die's punch pressure ,and reduce the force loading on the press machine.When stamping,large hole firstly punched after then punch the small hole.If punching large hole first,so that the material squeeze small upper die causing problem of upper die broken because of lack force.

2,Progressive die try to add block,notch french and pitch positioning device.

The regular positioning devices include fix stopper pin,guide pin,guide plate and notch french and so on...In the stamping,the fixed stopper pin is used for initial positioning,and the guide pin installed in the die is used to ensure the correct positioning of the strips when parts dropping.Notch french is used to control the feeding distance of strip, and the length notch french should be equal to pitch plus 0.05-0.5mm,also depending on the strip thickness.

3,The guide pin of progressive die should not be too long

We must note that the length of guide pin should not be too large,length into the guide hole also should not be too large,otherwise,the material feeding is not smooth,The length of guide pins should be thickness of guide pin fix plate plus the material thickness.

4,Complicated parts and long&thin parts should not be punched at one time in progressive die.

if process allows should be split into a number of punches, and step by step for stamping, which can be easier to machine the hole on tools and extend the service life, and easy to repair the mold then improve productivity.

5,Design should leave idle in order to adjust and modify tool later

Leave an empty station between the restrike station and the final part fall station in order to install stripper plate and lower die plate to improve the strength of the lower die.

6,Scraps jump-proof design

Change the shape of punch,Increase the adhesion of scrap to the cutting line punch with blow hole V-shaped or dovetail jamming of the cutting line

design reasonable punch clearance

7,The strip in the progressive can not be deformed

8,Tool components with function of quick change and fool-proof