Deep drawing is a metalworking process used to convert flat sheet metal into hollow parts with a depth greater than their diameter. This process is widely employed in various industries, including automotive, aerospace, and consumer goods, due to its ability to produce complex shapes with high precision and efficiency. As a leading supplier of deep draw parts, I understand the importance of having the right equipment to ensure the quality and consistency of the final products. In this blog post, I will discuss the essential equipment needed to make deep draw parts and how each piece contributes to the overall process.

Press Machines

The press machine is the heart of the deep drawing process. It provides the force required to shape the sheet metal into the desired form. There are several types of press machines available, each with its own advantages and limitations.

Mechanical Presses

Mechanical presses are the most common type of press used in deep drawing operations. They use a flywheel and a crankshaft mechanism to convert the rotational motion of the motor into linear motion, which is then used to apply force to the die. Mechanical presses are known for their high speed and precision, making them suitable for high-volume production. They can be further classified into two types: gap-frame presses and straight-side presses. Gap-frame presses are more versatile and can accommodate a wider range of die sizes, while straight-side presses offer greater stability and accuracy, making them ideal for large and complex deep draw parts.

Hydraulic Presses

Hydraulic presses use hydraulic fluid to generate force. They offer several advantages over mechanical presses, including greater control over the force and speed of the press, as well as the ability to apply a constant force throughout the stroke. Hydraulic presses are also quieter and more energy-efficient than mechanical presses. However, they are generally slower and more expensive to operate. Hydraulic presses are commonly used for deep drawing operations that require a high degree of precision and control, such as the production of automotive components and aerospace parts.

Dies

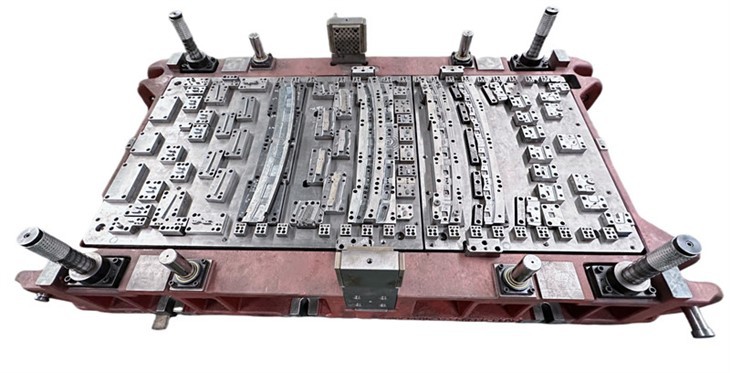

Dies are the tools used to shape the sheet metal into the desired form. They are typically made of high-strength steel or carbide and are designed to withstand the high pressures and forces involved in the deep drawing process. There are several types of dies used in deep drawing, including blanking dies, drawing dies, and trimming dies.

Blanking Dies

Blanking dies are used to cut the sheet metal into the desired shape before the deep drawing process begins. They consist of a punch and a die, which are designed to fit together precisely. The punch is forced through the sheet metal, cutting it into the desired shape. Blanking dies can be either single-stage or multi-stage, depending on the complexity of the shape. Single-stage blanking dies are used for simple shapes, while multi-stage blanking dies are used for more complex shapes that require multiple cuts.

Drawing Dies

Drawing dies are used to shape the blanked sheet metal into the desired form. They consist of a punch and a die cavity, which are designed to fit together precisely. The punch is forced into the die cavity, stretching the sheet metal and forming it into the desired shape. Drawing dies can be either single-action or double-action, depending on the complexity of the shape. Single-action drawing dies are used for simple shapes, while double-action drawing dies are used for more complex shapes that require multiple stages of drawing.

Trimming Dies

Trimming dies are used to remove any excess material from the deep drawn part after the drawing process is complete. They consist of a punch and a die, which are designed to fit together precisely. The punch is forced through the part, cutting off the excess material. Trimming dies can be either single-stage or multi-stage, depending on the complexity of the shape. Single-stage trimming dies are used for simple shapes, while multi-stage trimming dies are used for more complex shapes that require multiple cuts.

Lubrication Systems

Lubrication is an essential part of the deep drawing process. It helps to reduce friction between the sheet metal and the die, which in turn reduces the risk of tearing and wrinkling. Lubrication also helps to improve the surface finish of the deep drawn part and extends the life of the die. There are several types of lubrication systems available, including flood lubrication systems, spray lubrication systems, and roller lubrication systems.

Flood Lubrication Systems

Flood lubrication systems are the most common type of lubrication system used in deep drawing operations. They involve flooding the die and the sheet metal with a lubricant, such as oil or grease. Flood lubrication systems are simple and effective, but they can be messy and require a lot of lubricant.

Spray Lubrication Systems

Spray lubrication systems involve spraying the die and the sheet metal with a lubricant using a spray nozzle. Spray lubrication systems offer several advantages over flood lubrication systems, including greater control over the amount of lubricant applied, less waste, and a cleaner work environment. However, they require more maintenance and are generally more expensive than flood lubrication systems.

Roller Lubrication Systems

Roller lubrication systems involve applying the lubricant to the sheet metal using a roller. Roller lubrication systems offer several advantages over flood and spray lubrication systems, including greater uniformity of lubrication, less waste, and a cleaner work environment. However, they require more maintenance and are generally more expensive than flood and spray lubrication systems.

Material Handling Equipment

Material handling equipment is used to move the sheet metal and the deep drawn parts between the different stages of the manufacturing process. It includes equipment such as conveyors, robots, and cranes.

Conveyors

Conveyors are used to move the sheet metal and the deep drawn parts along a production line. They can be either belt conveyors or roller conveyors, depending on the type of material being handled. Conveyors offer several advantages over manual handling, including increased efficiency, reduced labor costs, and improved safety.

Robots

Robots are used to perform a variety of tasks in the deep drawing process, including loading and unloading the press, transferring the parts between the different stages of the manufacturing process, and inspecting the parts for quality. Robots offer several advantages over manual labor, including increased precision, speed, and consistency, as well as the ability to work in hazardous environments.

Cranes

Cranes are used to lift and move heavy objects, such as dies and large deep draw parts. They can be either overhead cranes or gantry cranes, depending on the size and weight of the objects being lifted. Cranes offer several advantages over manual handling, including increased efficiency, reduced labor costs, and improved safety.

Quality Control Equipment

Quality control equipment is used to ensure that the deep drawn parts meet the required specifications and standards. It includes equipment such as measuring instruments, inspection machines, and testing equipment.

Measuring Instruments

Measuring instruments are used to measure the dimensions and tolerances of the deep drawn parts. They include tools such as calipers, micrometers, and coordinate measuring machines (CMMs). Measuring instruments are essential for ensuring that the parts meet the required specifications and standards.

Inspection Machines

Inspection machines are used to detect any defects or flaws in the deep drawn parts. They include machines such as optical inspection machines, X-ray inspection machines, and ultrasonic inspection machines. Inspection machines are essential for ensuring that the parts are of high quality and free from defects.

Testing Equipment

Testing equipment is used to test the mechanical properties and performance of the deep drawn parts. They include machines such as tensile testing machines, hardness testing machines, and fatigue testing machines. Testing equipment is essential for ensuring that the parts meet the required mechanical properties and performance standards.

In conclusion, making deep draw parts requires a combination of high-quality equipment and skilled operators. The press machine, dies, lubrication systems, material handling equipment, and quality control equipment all play a crucial role in the deep drawing process. As a leading supplier of deep draw parts, we have invested in the latest equipment and technology to ensure that we can produce high-quality deep draw parts that meet the needs of our customers. If you are in need of deep draw parts or have any questions about the deep drawing process, please feel free to [initiate a procurement discussion with us]. We look forward to working with you to meet your deep draw part needs.

References

- Kalpakjian, S., & Schmid, S. R. (2008). Manufacturing Engineering and Technology (5th ed.). Pearson Prentice Hall.

- Dieter, G. E. (1988). Mechanical Metallurgy (3rd ed.). McGraw-Hill.

- Groover, M. P. (2010). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems (4th ed.). Wiley.