Hey there! As a stamping die supplier, I've seen my fair share of stamping die failures over the years. It's a headache for everyone involved - from the manufacturers who rely on these dies to produce high - quality parts to us suppliers who want to ensure our products perform at their best. In this blog, I'm gonna share some tips on how to prevent stamping die failure.

1. Proper Material Selection

The first step in preventing stamping die failure is choosing the right materials. You know, different stamping applications require different types of die materials. For example, if you're working on a project that involves high - volume production, you'll need a die material that can withstand a lot of wear and tear. Tool steels are often a great choice in these cases because they're hard, tough, and can handle the repeated impacts and pressures of stamping operations.

On the other hand, if you're dealing with a more specialized application, like forming a complex shape, you might need a material with better machinability and formability. Some alloys can offer these properties, allowing you to create dies that can precisely shape the parts you need. It's all about matching the material to the job. And as a supplier, we always work closely with our clients to understand their specific needs and recommend the most suitable die materials.

2. Regular Maintenance

Maintenance is key when it comes to preventing stamping die failure. Just like you wouldn't neglect your car's maintenance, you can't ignore the upkeep of your stamping dies. Regular cleaning is a must. During the stamping process, debris, lubricants, and metal shavings can accumulate on the die surfaces. If not cleaned properly, this buildup can cause abrasion, corrosion, and other issues that can lead to die failure.

We usually recommend using appropriate cleaning agents and tools to remove the dirt and contaminants. Also, inspecting the dies for signs of wear, cracks, or other damage on a regular basis is crucial. Early detection of problems can save you a lot of time and money in the long run. For instance, if you notice a small crack in the die, you can repair it before it grows and causes the entire die to fail.

3. Correct Heat Treatment

Heat treatment plays a vital role in the performance and longevity of stamping dies. The right heat treatment can enhance the hardness, toughness, and wear resistance of the die material. When we manufacture stamping dies, we pay close attention to the heat treatment process. We make sure to follow the correct heating and cooling cycles to achieve the desired properties.

If the heat treatment is done incorrectly, the die might be too brittle or too soft. A brittle die is more likely to crack under pressure, while a soft die can wear out quickly. So, it's really important to have a well - controlled heat treatment process. We have a team of experts who are well - versed in heat treatment techniques, and they ensure that every die we supply meets the highest quality standards.

4. Adequate Lubrication

Lubrication is another important factor in preventing stamping die failure. During the stamping process, there's a lot of friction between the die and the workpiece. Without proper lubrication, this friction can cause excessive wear on the die surfaces, increase the forming force required, and even lead to galling or sticking of the workpiece to the die.

We recommend using high - quality lubricants that are specifically designed for stamping operations. These lubricants can reduce friction, dissipate heat, and protect the die from corrosion. The amount and application method of the lubricant also matter. Too little lubrication won't be effective, while too much can cause other problems like mess and waste. So, it's all about finding the right balance.

5. Optimal Design

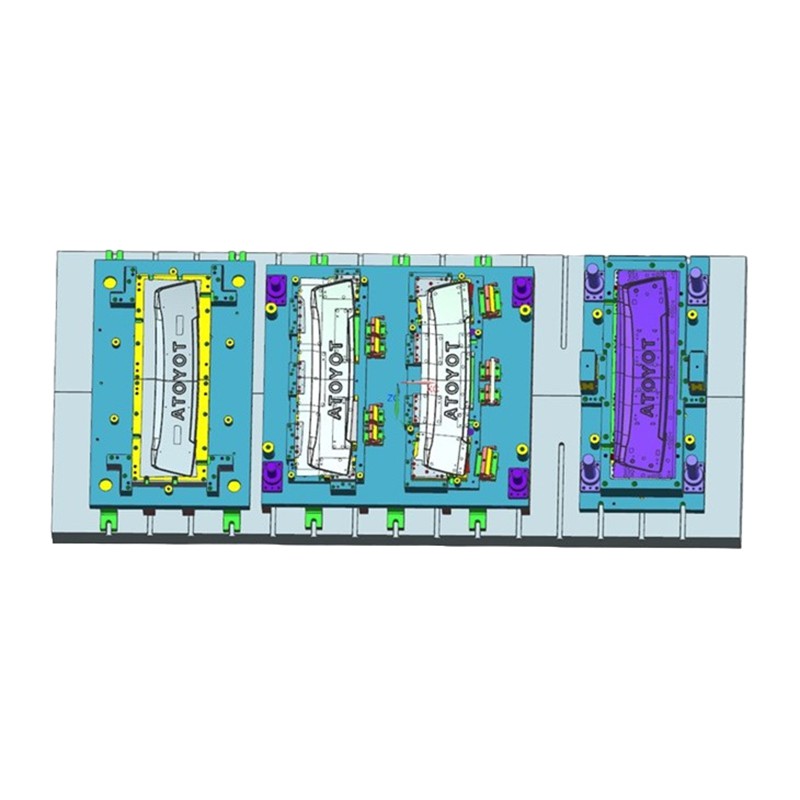

The design of the stamping die is fundamental to its performance. A well - designed die can evenly distribute the forming forces, reduce stress concentrations, and ensure smooth operation. When designing a die, we take into account factors such as the shape and size of the workpiece, the stamping process (like transfer die stamping), and the production volume.

For example, if the die has sharp corners or sudden changes in cross - section, it can create stress concentrations that may lead to cracking. So, we try to use rounded corners and smooth transitions in the design. Also, we optimize the die structure to make it easy to assemble, disassemble, and maintain. This way, we can minimize the chances of die failure and improve the overall efficiency of the stamping process.

6. Operator Training

Last but not least, the operators who use the stamping dies play a huge role in preventing die failure. They need to be properly trained on how to operate the stamping equipment and handle the dies correctly. An untrained operator might make mistakes like overloading the die, using the wrong forming parameters, or mishandling the die during setup and removal.

We offer training programs for our clients' operators. In these programs, we teach them about the proper use of the stamping dies, how to recognize signs of potential problems, and what to do in case of an emergency. By having well - trained operators, we can significantly reduce the risk of stamping die failure.

In conclusion, preventing stamping die failure requires a comprehensive approach that involves proper material selection, regular maintenance, correct heat treatment, adequate lubrication, optimal design, and operator training. As a stamping die supplier, we're committed to providing our clients with high - quality dies and the support they need to keep these dies in top - notch condition.

If you're in the market for stamping dies or need advice on preventing die failure, don't hesitate to reach out to us. We're here to help you with all your stamping die needs and ensure that your production runs smoothly. Let's work together to achieve great results!

References

- "Stamping Die Design and Manufacturing" - Industry - specific handbook

- "Advanced Materials for Stamping Dies" - Academic research on die materials

- "Best Practices in Stamping Die Maintenance" - Technical articles from stamping industry magazines