Hey there! As a stamping die supplier, I've seen firsthand how crucial it is to optimize the stamping die layout. A well - optimized layout can save costs, improve efficiency, and enhance the quality of the stamped parts. In this blog, I'll share some tips and tricks on how to achieve that.

Understanding the Basics of Stamping Die Layout

Before we dive into the optimization process, let's quickly go over what stamping die layout is. It's basically the way the individual stamping operations are arranged within the die to transform a flat sheet of metal into the desired part. This includes things like blanking, piercing, bending, and forming operations.

The layout has a direct impact on the production speed, material utilization, and the overall quality of the stamped parts. If the layout is poorly designed, you might end up with wasted material, longer cycle times, and parts that don't meet the required specifications.

Factors Affecting Stamping Die Layout

There are several factors that you need to consider when designing or optimizing a stamping die layout.

Part Geometry

The shape and size of the part you're stamping play a huge role. Complex geometries might require multiple operations and more precise alignment. For example, if you're stamping a part with a lot of curves and bends, you'll need to plan the bending sequence carefully to avoid any distortion.

Material Properties

Different metals have different properties, such as ductility, hardness, and thickness. These properties can affect how the metal behaves during the stamping process. For instance, a softer metal might be more prone to stretching, while a harder one might require more force to cut. You need to take these into account when determining the layout and the type of stamping operations.

Production Volume

If you're producing a large number of parts, you'll want to optimize the layout for high - speed production. This might involve using progressive dies or transfer die stamping. Transfer die stamping is great for larger parts or when you need to perform complex operations. It allows you to transfer the part between different stations in the die, which can significantly increase the production rate.

Tips for Optimizing Stamping Die Layout

1. Minimize Material Waste

One of the biggest cost factors in stamping is the material. By optimizing the layout, you can reduce the amount of scrap. You can do this by nesting the parts as closely as possible on the sheet metal. There are software tools available that can help you find the most efficient nesting pattern based on the part shape and the size of the sheet.

Another way to minimize waste is to use the scrap from one part as the starting material for another smaller part. This is called "scrap utilization" and can be a great way to save on material costs.

2. Streamline the Stamping Operations

Try to simplify the stamping process as much as possible. Combine multiple operations into a single step whenever it's feasible. For example, if you need to pierce a hole and then bend the metal around it, you might be able to design the die to do both operations at the same time. This can reduce the cycle time and the number of stations in the die.

3. Ensure Proper Alignment

Accurate alignment is crucial for producing high - quality parts. Make sure that the die is designed in such a way that the part is properly aligned at each station. You can use guide pins, locators, and other alignment features to ensure that the part stays in the correct position during the stamping process.

4. Consider the Die Maintenance

A well - designed layout should also take into account the ease of die maintenance. Make sure that the die components are easily accessible for cleaning, lubrication, and replacement. This can reduce downtime and extend the lifespan of the die.

Using Technology to Optimize Stamping Die Layout

In today's digital age, there are many software tools available that can help you optimize the stamping die layout. These tools use advanced algorithms to analyze the part geometry, material properties, and production requirements.

Simulation Software

Simulation software allows you to virtualize the stamping process. You can see how the metal will flow, where the stresses will occur, and if there are any potential issues with the layout. This can help you make adjustments to the layout before the die is actually built, saving you time and money.

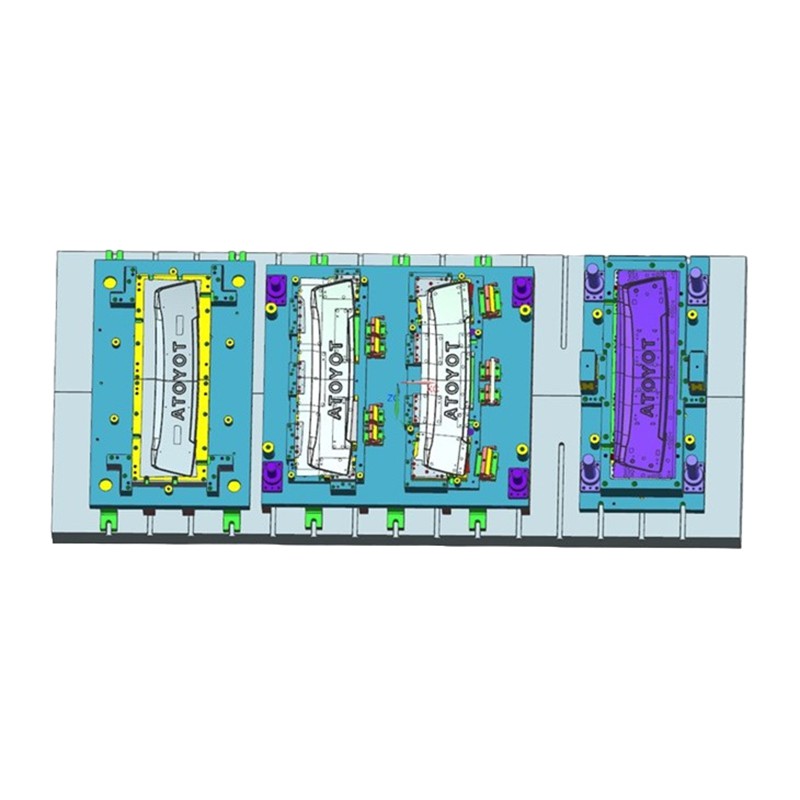

CAD/CAM Systems

CAD (Computer - Aided Design) and CAM (Computer - Aided Manufacturing) systems are essential for designing and manufacturing stamping dies. They allow you to create detailed 3D models of the die and the stamped parts. You can also use these systems to generate the tool paths for the machining operations, ensuring that the die is manufactured with high precision.

Case Studies: Successful Stamping Die Layout Optimization

Let me share a couple of real - world examples of how stamping die layout optimization can make a big difference.

Case Study 1: Automotive Parts Manufacturer

An automotive parts manufacturer was producing a complex engine component. The original stamping die layout had a high scrap rate and long cycle times. By using simulation software, they were able to optimize the nesting pattern and streamline the stamping operations. They reduced the scrap rate by 20% and increased the production rate by 30%.

Case Study 2: Electronics Manufacturer

An electronics manufacturer was stamping small metal parts for their devices. They were using a traditional die layout that was not very efficient. After implementing a new layout that combined multiple operations and improved the alignment, they were able to reduce the production cost by 15% and improve the part quality.

Conclusion

Optimizing the stamping die layout is a critical step in the stamping process. By considering factors like part geometry, material properties, and production volume, and by using the right techniques and technology, you can achieve significant cost savings, improve efficiency, and enhance the quality of the stamped parts.

If you're looking to optimize your stamping die layout or need a high - quality stamping die, don't hesitate to reach out. We're here to help you with all your stamping die needs. Whether it's a simple part or a complex one, we have the expertise and the technology to design and manufacture the perfect stamping die for you. Contact us for a quote and let's start a productive discussion on how we can improve your stamping operations.

References

- "Stamping Die Design Handbook" by X. Y. Zhang

- "Advanced Manufacturing Technology for Stamping" by John Smith

- Industry whitepapers on stamping die optimization