Hey there! I'm a supplier of stamping dies, and I've been in this business for quite a while. One question I get asked a lot is, "How can I improve the efficiency of a stamping die?" Well, in this blog post, I'm going to share some tips and tricks that I've learned over the years to help you get the most out of your stamping dies.

1. Design Optimization

The first step in improving the efficiency of a stamping die is to start with a good design. A well-designed die can reduce the number of operations, minimize waste, and improve the overall quality of the stamped parts. Here are some key points to consider during the design phase:

- Simplify the Process: Try to reduce the number of steps in the stamping process. For example, instead of having multiple punching and bending operations, see if you can combine them into one. This not only saves time but also reduces the wear and tear on the die.

- Use the Right Materials: Selecting the appropriate materials for the die is crucial. High-quality materials can withstand more cycles, reduce the risk of breakage, and improve the surface finish of the stamped parts. Consider using materials with good hardness, toughness, and wear resistance.

- Optimize the Layout: Arrange the components of the die in a way that minimizes the travel distance of the material. This can reduce the cycle time and improve the overall efficiency of the stamping process. Additionally, make sure to leave enough space for easy access and maintenance.

2. Maintenance and Lubrication

Regular maintenance and proper lubrication are essential for keeping a stamping die in good working condition. Here's what you need to do:

- Clean the Die Regularly: Remove any debris, dirt, or metal shavings from the die after each use. This helps prevent the build-up of contaminants, which can cause damage to the die and affect the quality of the stamped parts.

- Inspect for Wear and Damage: Periodically check the die for signs of wear, such as dull edges, cracks, or excessive clearance. Replace any worn or damaged components immediately to avoid further problems.

- Lubricate the Moving Parts: Apply a suitable lubricant to the moving parts of the die, such as the punches, dies, and guides. Lubrication reduces friction, heat, and wear, which can extend the life of the die and improve its performance.

3. Operator Training

The efficiency of a stamping die also depends on the skills and knowledge of the operators. Providing proper training to your operators can help them use the die correctly, avoid common mistakes, and improve the overall productivity of the stamping process. Here are some training topics to cover:

- Die Operation: Teach the operators how to set up, adjust, and operate the stamping die safely and efficiently. Make sure they understand the different functions of the die components and how to troubleshoot common problems.

- Quality Control: Train the operators on how to inspect the stamped parts for quality. Teach them to identify defects, such as burrs, cracks, or dimensional variations, and how to take corrective actions.

- Safety Procedures: Emphasize the importance of safety when working with stamping dies. Train the operators on how to use personal protective equipment (PPE), follow safety protocols, and avoid potential hazards.

4. Process Monitoring and Optimization

Monitoring the stamping process and making adjustments as needed can help you identify and address any issues that may affect the efficiency of the die. Here are some ways to monitor and optimize the process:

- Collect Data: Use sensors and monitoring devices to collect data on key process parameters, such as pressure, temperature, and cycle time. Analyze this data to identify trends and patterns that can help you optimize the process.

- Make Adjustments: Based on the data analysis, make adjustments to the stamping process, such as changing the punch speed, pressure, or lubrication. Continuously monitor the results to ensure that the adjustments are having the desired effect.

- Implement Lean Manufacturing Principles: Apply lean manufacturing principles, such as reducing waste, improving flow, and increasing productivity, to the stamping process. This can help you eliminate non-value-added activities and improve the overall efficiency of the operation.

5. Upgrade to Advanced Technologies

Investing in advanced technologies can significantly improve the efficiency of a stamping die. Here are some technologies to consider:

- Automation: Automate the stamping process using robots or other automated equipment. This can reduce the cycle time, improve the accuracy and consistency of the stamped parts, and free up operators to perform other tasks.

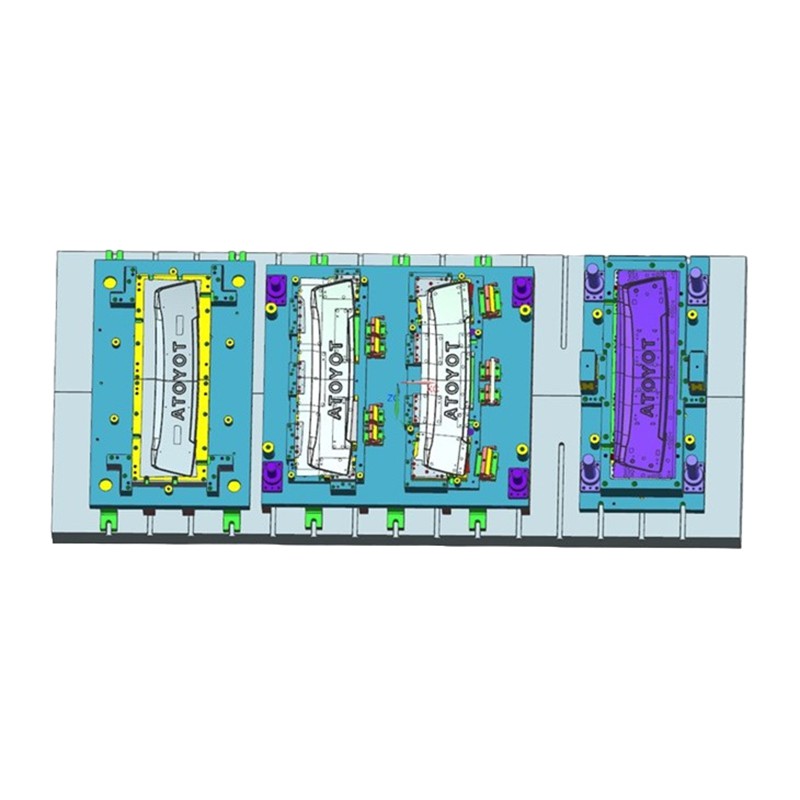

- Transfer Die Stamping: Transfer die stamping is a more advanced stamping technique that allows for the production of complex parts in a single operation. This can significantly reduce the number of steps in the stamping process and improve the overall efficiency.

- CAD/CAM Software: Use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to design and manufacture the stamping die. This can improve the accuracy and precision of the die, reduce the design and manufacturing time, and allow for easy modifications and improvements.

Conclusion

Improving the efficiency of a stamping die requires a combination of good design, regular maintenance, proper operator training, process monitoring, and the use of advanced technologies. By following these tips and tricks, you can increase the productivity of your stamping operation, reduce costs, and improve the quality of the stamped parts.

If you're interested in learning more about how we can help you improve the efficiency of your stamping dies, please don't hesitate to contact us. We're always happy to discuss your specific needs and provide you with customized solutions.

References

- "Stamping Die Design Handbook" by John Doe

- "Advanced Manufacturing Technologies for Stamping Dies" by Jane Smith

- "Lean Manufacturing in the Stamping Industry" by Bob Johnson